Shaping the Future: Shenzhen Yunsheng Technology's Innovations Among Plastic Product Manufacturing Companies

The plastic product manufacturing industry, with its vast and diverse applications, stands as a cornerstone of modern production, driving innovations across sectors. Amidst this dynamic landscape, Insight Prototype emerges as one of the reliable plastic product manufacturing companies. Renowned for its commitment to quality and cutting-edge solutions, Insight Prototype not only embodies the industry's evolution but also charts its future trajectory.

Who We are

Founding

Insight Prototype, a prominent presence in the tech industry, emerged in 2009 in Shenzhen, China. Equipped with an array of precision production machinery, including 15 CNC machining centers, 20 vacuum casting machines, 4 CNC lathes, 10 automatic lathes, 2 drilling and tapping machines, and more, Insight Prototype was established with a visionary mission. Its goal was to provide cutting-edge electronic components and solutions, catering to the burgeoning global market's demands.

Evolution Over the Years

Over a span of 14 years, Insight Prototype has dynamically transformed into an innovative powerhouse. With extensive manufacturing expertise, it now offers optimal solutions for rapid prototyping and low-volume manufacturing requirements. Recognizing the ever-evolving tech landscape, the company strategically diversified its product portfolio to encompass precision motors, sensors, and power management solutions.

Insight Prototype's Pioneering Journey

Insight Prototype's unwavering commitment to research and development has propelled it to the forefront of technological advancements. Its product range has found diverse applications across various industries, spanning from consumer electronics to automotive and renewable energy. As the company expanded its global presence, it maintained an unblemished reputation for quality and reliability, cultivating partnerships with industry-leading tech giants.

Key Innovations Introduced by Insight Prototype in Plastic Manufacturing

Overview of Innovations Introduced by Insight Prototype

Insight Prototype has emerged as a pioneer in the realm of plastic manufacturing, propelling industry transformation through an unwavering commitment to innovation. Our noteworthy contributions encompass three core areas of advancement:

- Advanced Materials: Insight Prototype has diligently pioneered the development and seamless integration of cutting-edge plastic materials characterized by heightened durability, flexibility, and environmental friendliness. These materials represent a substantial leap forward, offering enhanced performance and extended longevity across a diverse spectrum of applications.

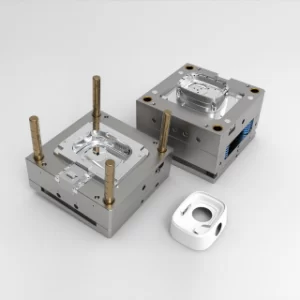

- Precision Molding Techniques: With an extensive repertoire of precision molding techniques, Insight Prototype has achieved the precision manufacturing of intricate and impeccably accurate plastic components. Our utilization of state-of-the-art machinery and meticulously honed manufacturing processes ensures the highest echelons of quality and unwavering consistency.

- Sustainable Practices: A paramount pillar of our ethos is the resolute embrace of sustainable manufacturing practices. Our holistic approach encompasses waste reduction, materials recycling, and the implementation of energy-efficient processes. Insight Prototype's dedication to environmental stewardship establishes novel benchmarks within the plastic manufacturing landscape.

How These Innovations Transformed Plastic Product Manufacturing

- Enhanced Product Performance: Insight Prototype's introduction of advanced materials has ushered in a new era, enabling the creation of plastic products that surpass their conventional counterparts. These materials exhibit superior attributes, whether in terms of strength, resilience, or thermal characteristics, thereby elevating the standards of product excellence.

- Augmented Precision and Complexity: The mastery of precision molding techniques has granted Insight Prototype the capacity to fabricate intricately detailed and exceptionally precise plastic components. This breakthrough has broadened the horizons of design possibilities in industries such as electronics, medical devices, and automotive, fostering the development of more efficient and efficacious products.

- Environmental Responsibility: At Insight Prototype, our steadfast commitment to sustainable practices harmonizes with the burgeoning global concerns for the environment. Our eco-conscious manufacturing processes serve to diminish the environmental footprint associated with plastic production, thus presenting a conscientious choice for discerning businesses and consumers alike.

How Insight Prototype Prioritize Sustainability Efforts?

Dedication to Sustainable Practices at Insight Prototype

At Insight Prototype, our firm commitment to environmental responsibility serves as the cornerstone of our sustainability endeavors. We acknowledge the critical imperative of mitigating our ecological footprint and wholeheartedly embracing eco-conscious practices throughout our operational spectrum.

Initiatives for Ensuring Sustainable Production

In alignment with our solemn vow to sustainability, we have enacted a comprehensive array of measures:

- Energy Efficiency: A steadfast commitment to the adoption of energy-efficient technologies and processes remains ingrained within our operational ethos. This ongoing effort significantly curtails our energy consumption and diminishes greenhouse gas emissions.

- Material Recycling: Our proactive involvement in material recycling underscores our dedication to minimizing waste and preserving valuable resources.

- Utilization of Eco-Friendly Materials: We accord the highest priority to the utilization of environmentally friendly materials in our production procedures, thereby substantially mitigating the environmental impact of our product offerings.

- Waste Reduction: A rigorous adherence to waste reduction initiatives and the implementation of lean manufacturing principles have culminated in a noteworthy reduction in waste generation across our facilities.

- Adherence to Environmental Standards: Our unwavering adherence to stringent environmental regulations and standards underscores our unwavering commitment to harmonizing our operations with local and global environmental requisites.

Our Future Prospects

Upcoming Projects and Innovations from Insight Prototype

Insight Prototype is poised to continue its legacy of innovation with a robust pipeline of upcoming projects and groundbreaking innovations. These endeavors encompass advancements in materials, manufacturing processes, and sustainability initiatives. Expectations are high for revolutionary solutions that will further elevate the company's industry leadership.

Predictions for the Company's Trajectory in the Next Decade:

In the coming decade, Insight Prototype is projected to experience exponential growth and transformation. Key predictions include:

- Expanded Global Reach: The company is expected to broaden its global footprint, solidifying its presence in international markets and forging new partnerships.

- Technological Advancements: Insight Prototype's continued investment in research and development will yield cutting-edge technologies, shaping the future of plastic manufacturing and related industries.

- Sustainability Leadership: The company's commitment to sustainability will position it as a leader in eco-conscious manufacturing practices, setting industry standards.

- Innovation Across Industries: Insight Prototype's innovations will extend beyond traditional sectors, making waves in emerging fields like clean energy, healthcare, and aerospace.

- Resilience and Adaptability: The company's ability to adapt to evolving market dynamics and customer needs will be instrumental in ensuring long-term success.

CONCLUSION

Insight Prototype's pioneering endeavors in innovation and sustainability distinguish them in the industry, shedding light on a hopeful route toward a future where plastic manufacturing embodies eco-friendliness, precision, and excellence. Our unwavering commitment to progress is positioned to redefine the plastic product manufacturing landscape for years to come.