About Us

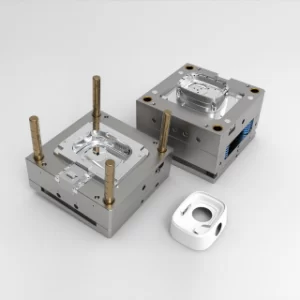

Insight prototype Co., Ltd was established in 2009, covering an area of 2000 square meters. The factory is located in Shenzhen City, Guangdong Province, China. We have all kinds of precision production machines, 15 sets of CNC machining centers, 20 sets of vacuum casting machines, 4 sets of CNC lathes, 10 sets of automatic lathes, 2 sets of drilling and tapping machines, etc. We are specialized in supplying rapid prototypes, CNC machining parts, precision turning parts , Die-casting parts, injection molding parts, investment casting parts, stamping parts. All products 100% meet the requirements of customer drawings and meet international quality standards. We have advanced perfect testing equipment (CMM, Projector, Hardness Tester, Roughness Tester, Density Tester, Precision Hole Gauge...), which can help us provide customers with a complete quality control report before shipment to obtain Delivery approval ensures minimal scrap.

Our team

Insight prototype Co., Ltd has 13 years of experience in the industry, and with years of manufacturing experience, provides the best solution for all rapid prototyping and low-volume manufacturing needs.

Our Mission

Customer first, quality first, service first, efficiency first

Our Vision

We are committed to bringing the best service to every company and every R&D team.

As our global network provides virtually limitless capacity, your parts go directly into production at the most competitive prices.

Why Choose Us

Insight prototype Co., Ltd has 13 years of experience in the industry, and with years of manufacturing experience, provides the best solution for all rapid prototyping and low-volume manufacturing needs.

Part Quality Ensured By Expertise Experience

Insight pride in stict quaity controlstandards applied throughout each section of our production process.Our expert quality auditors pay close attention to detail, inspecting each product for inconsistencies.

Expert Technical Support

Our factory holds an lSo9001:2015 certificate - a testament to our dedication to quality.

Strict Standard

The facility complies with established manufacturing standards, like DIN-2768-fine, ect.

Well-vetted Suppliers

Close partnerships with thousands of reliable material suppliers guarantee constant accessto quality materials.

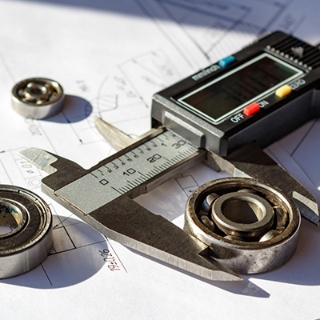

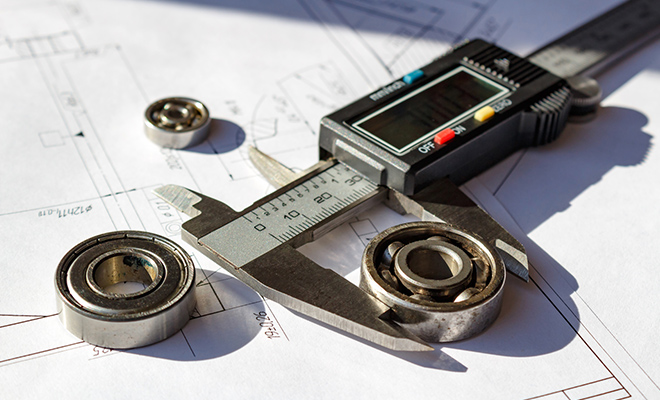

Advanced Testing Facilities

Completed prototypes go through various testing machines, like profile projectors, CMM, and 3D scanners.

Rigorous Qualitg System

Our strict commitment to quality control regulations ensures consistent quality throughout the production process.

Complete Qualitg Report

Get comprehensive quality reports from our in-house quality team or third-party labs.