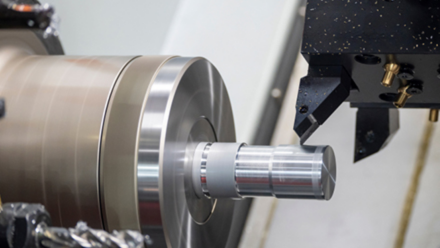

Custom Online CNC Machining Services

On-demand CNC machining for rapid prototyping and production parts, through a network of specialized, experienced and thoroughly vetted CNC machine shops.

CNC Machining Services

If you need custom machined parts with complex geometries, or get end-use products in the shortest possible time, Insightprototype is good enough to break through all of that and achieve your idea immediately.

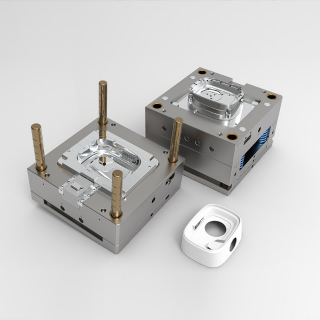

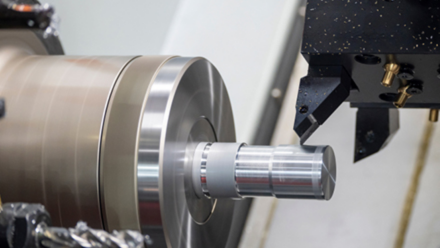

From CNC Prototyping to Production

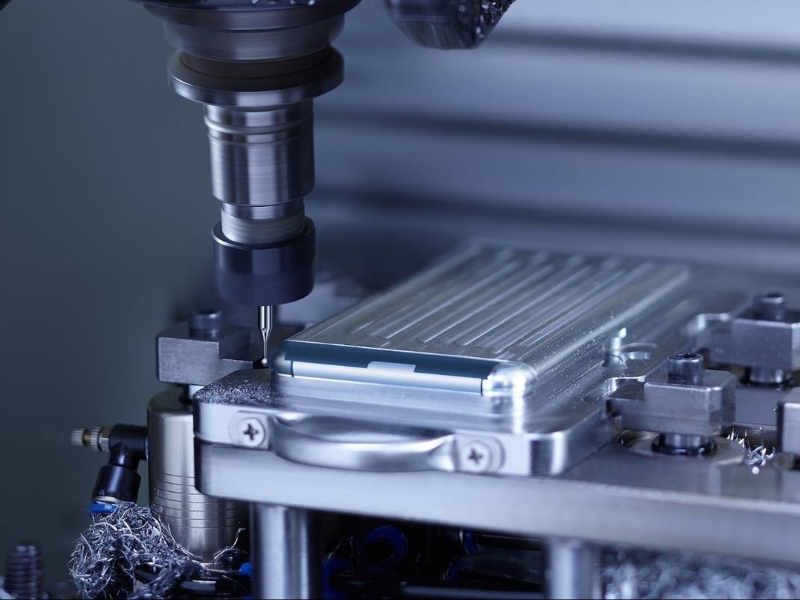

CNC machining is a computerized, versatile manufacturing process ideal for rapid prototyping and on-demand production.

Insightprototype Prototyping

With our instant quotation platform and strong capacity, you can get excepted prototypes in short lead times. This allows you to quickly test prototype parts and get them to market.

Insightprototype Prototyping

With our instant quotation platform and strong capacity, you can get excepted prototypes in short lead times. This allows you to quickly test prototype parts and get them to market.

Insightprototype Prototyping

With our instant quotation platform and strong capacity, you can get excepted prototypes in short lead times. This allows you to quickly test prototype parts and get them to market.

CNC Machining Materials

A numebr of materials can be used in CNC machines, giving you various of options to complete rapid prototyping to production runs of custom complex parts. For your manufacturing needs, we provide instant quotatios of 100+ metals and plastics, and even you can compare prices for different machining materials.

-

Aluminum

-

Copper

-

Brass

-

Stainless Steel

-

Titanium

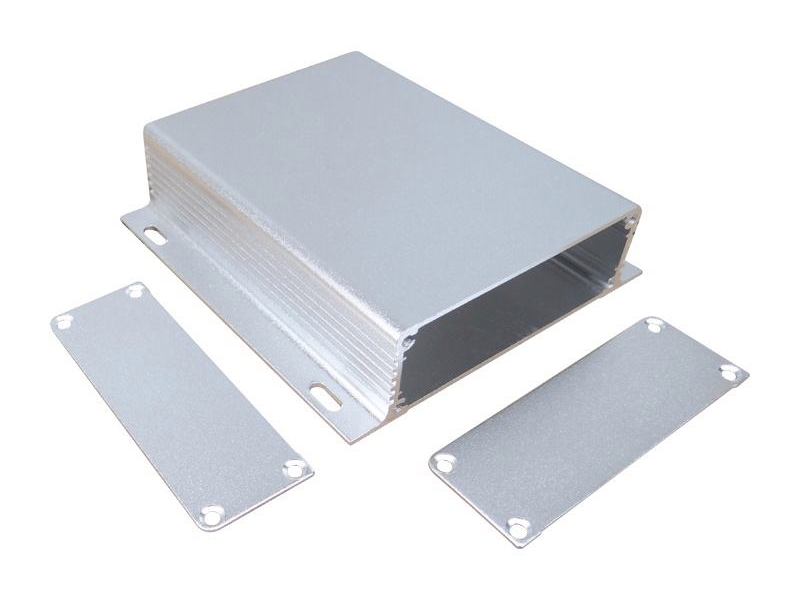

Aluminum

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

- Lead Time: < 10 days

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Copper

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

- Lead Time: < 10 days

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Brass

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

- Lead Time: < 10 days

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Stainless Steel

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

- Lead Time: < 10 days

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Titanium

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

- Lead Time: < 10 days

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

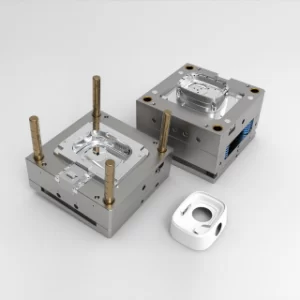

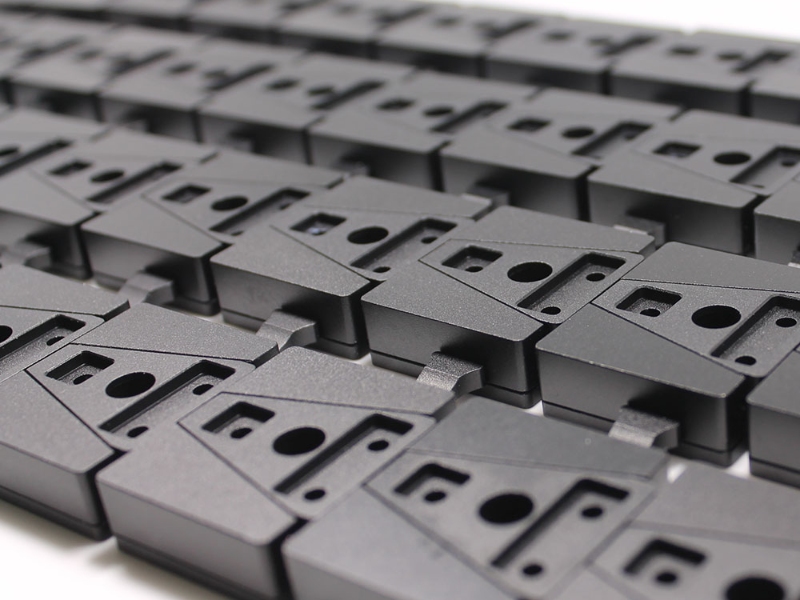

Small Molded Parts within Days

Insightprototype makes it faster, easier, and more efficient to source the custom-manufactured parts you need, precisely when and how you need them.

CNC Machining Materials

A numebr of materials can be used in CNC machines, giving you various of options to complete rapid prototyping to production runs of custom complex parts. For your manufacturing needs, we provide instant quotatios of 100+ metals and plastics, and even you can compare prices for different machining materials.

| Name | Description | Material | Color | Texture | |

|---|---|---|---|---|---|

|

Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish. |

|

Bead Blasting | Bead blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments. | ABS, Aluminum, Brass, Stainless Steel, Steel | ----- | Matte |

|

Powder Coating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-glos |

CNC Machining Materials

Our robust production capabilities, comprehensive services, and strong quality control offer fast and cost-effective solutions that will help you improve your brand.

What Our Customers Say

A customer's words have a more substantial impact than a company's claims - and see what our satisfied customers have said regarding how we fulfilled their requirements.

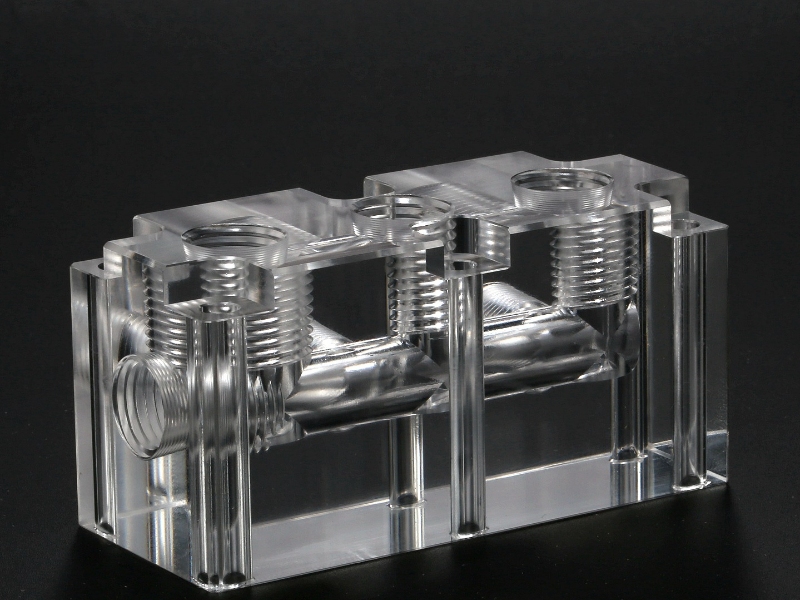

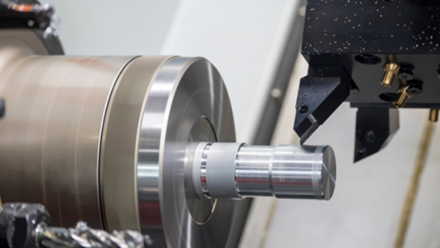

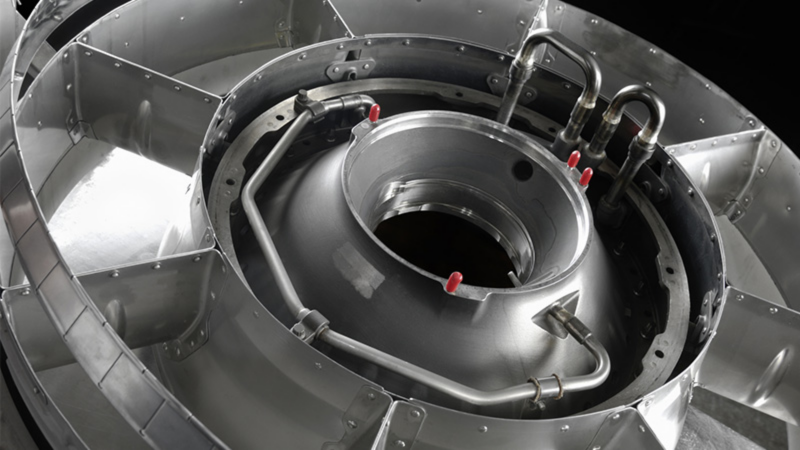

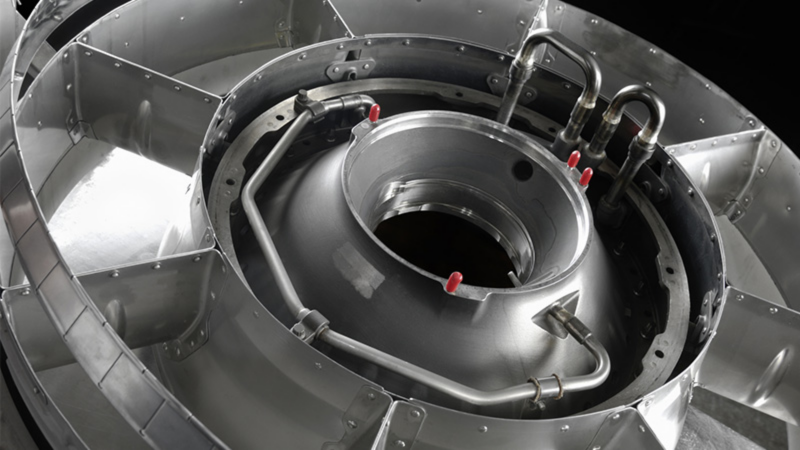

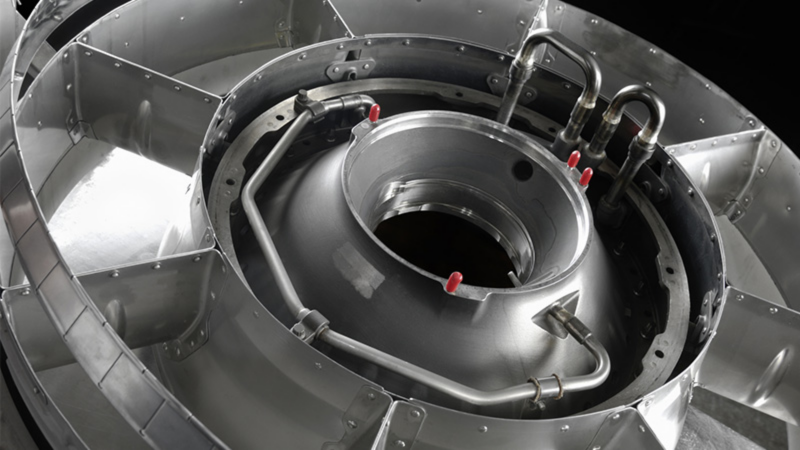

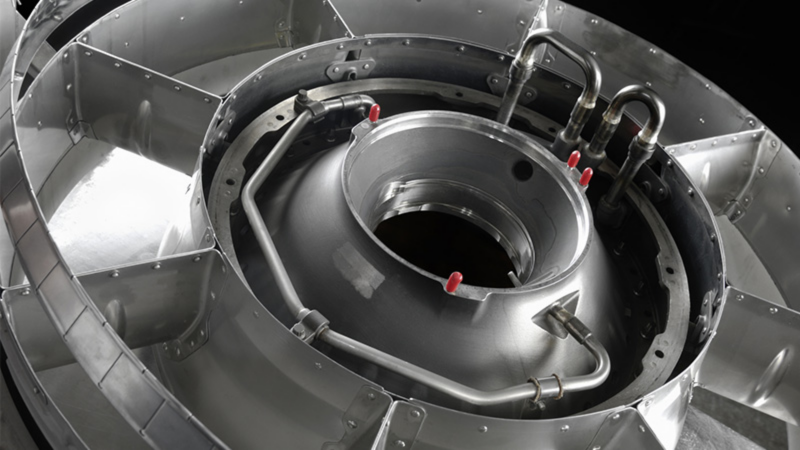

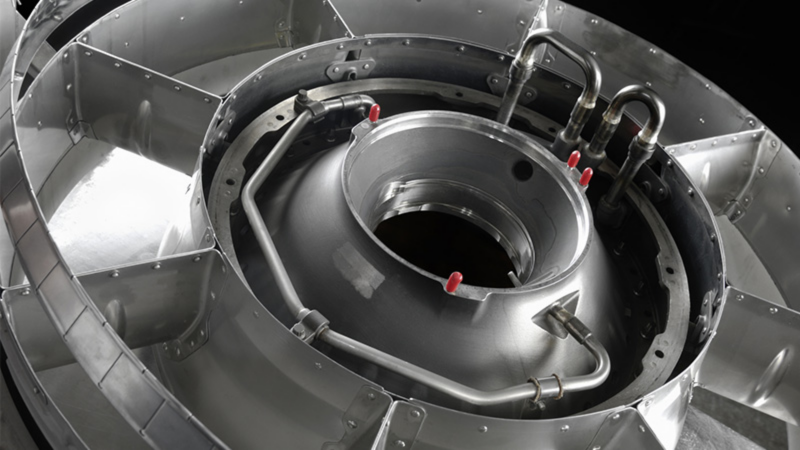

Gallery of CNC Machined Parts

Check out our extensive gallery that shows precision machined prototypes and parts from our valued customers.

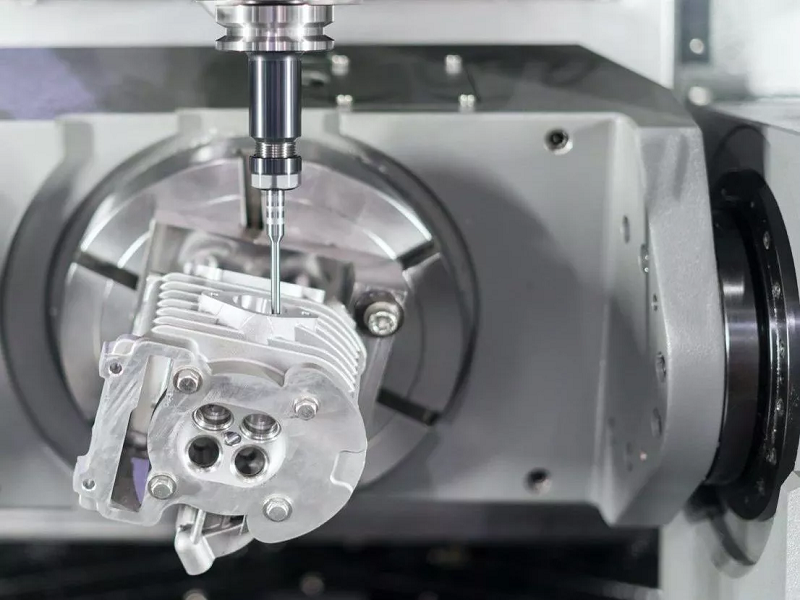

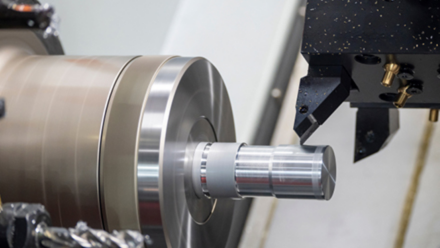

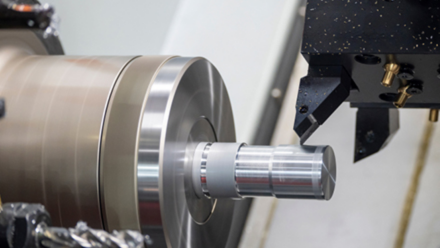

About the CNC Milling Process

With milling, the stock that the part will be cut from is usually a six-sided bar or sheet of material (though it can be also a cylindrical rodi). This stock is fixtured to the bed of the machine and the features of the part are cut using a rotating tool such as a drill or endmill.

Frequently Asked Questions

1.What are your maximum dimensions for CNC machining?

2.What are your maximum dimensions for CNC machining?

3.What are your maximum dimensions for CNC machining?

4.What are your maximum dimensions for CNC machining?

Latest Blog Posts

Follow Insightprototype to learn more CNC industry information!