Insert Molding

Insert molding is an injection molding technique that involves injecting a plastic material around a plastic or metal inse placed in a mold cavity. The insert is pre-placed in the mold cavity, after which the plastic is injected. On cooling, this forms a solid part that is strong and durable. RapidDirect plastic insert molding services allow you to make a strong and permanent bond between the insert and molded plastic.

Production Grade Quality

ISO 9001:2015 certificated

24/7 Engineering Support

Home > Service > lnjection Molding >

Unmatched Lead Time

Complex Geometries Support

Flexible Color Options

Material and Finishing Selection

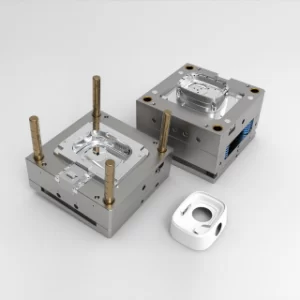

What's Insert Molding

Insert molding is an injection molding technique that involves injecting a plastic material around a plastic or metal insert placed in a mold cavity. The insert is pre-placed in the mold cavity, after which the plastic is injected. On cooling, this forms a solid part that is strong and durable. RapidDirect plastic insert molding services allow you to make a strong and permanent bond between the insert and molded plastic.