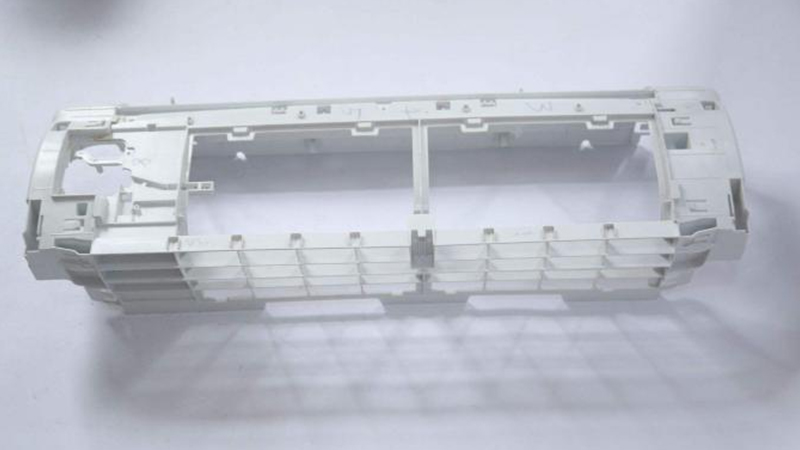

Furniture and home appliances

Furniture and home appliances is an air conditioner shell with a relatively complicated structure. The customer made several sample tests before injection molding. We used a total of two processes for testing. One is to use the process of CNC numerical control machine tools to conduct splicing tests; the other is to use vacuum injection molding. Yunsheng Technology can provide one-stop service and save cost.

CNC furniture and home appliance solutions refers to the use of CNC machining technology to manufacture furniture and home appliance products. This solution makes full use of the advantages of CNC technology, such as high precision, high production efficiency, good repeatability, etc., to achieve high-quality, efficient furniture and home appliances production.

CNC furniture solutions mainly include the following aspects:

- Design and manufacturing: Furniture design through CAD design software, and the use of CNC machine tools for high-precision cutting, engraving and other processing, can produce complex shapes of furniture products.

- Material selection: CNC machining can be applied to a variety of materials, such as wood, plate, metal, etc., can be selected according to the needs of the appropriate materials for processing to meet the production requirements of different furniture.

- Fine processing: CNC machine tools can achieve high-precision cutting and engraving, can make furniture products with fine details and stable structure, and improve the quality of products.

- Mass production: CNC technology has the characteristics of high efficiency and good repeatability, which can realize the mass production of furniture, improve production efficiency and reduce costs.

CNC home appliance solutions mainly include the following aspects:

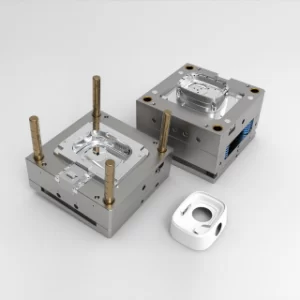

- Shell manufacturing: The use of CNC technology can produce a variety of shapes of home appliance shell, such as TV shell, refrigerator shell, etc., to meet the design and manufacturing needs of different home appliance products.

- Parts processing: CNC machine tools can carry out accurate parts processing, such as circuit boards, radiators, motors, etc., to improve the performance and stability of home appliances.

- Production efficiency: CNC technology can achieve mass production of home appliances, improve production efficiency and reduce production costs, and adapt to changes in market demand.

- Innovative design: CNC technology can realize the processing of complex shapes, which can meet the needs of innovative design of home appliances and improve the competitiveness of products.

In short, CNC furniture and home appliance solutions through the application of CNC machining technology, you can achieve high-quality, efficient furniture and home appliance manufacturing, enhance product competitiveness.