Polyurethane Vacuum Casting

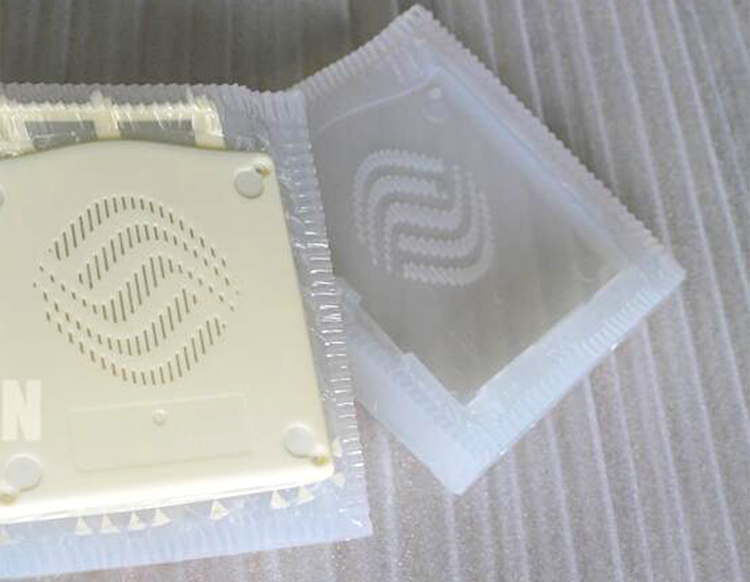

For successful vacuum casting, a prototype is first created by expert engineers using CNC machining or 3D printing techniques. After the prototype is finalized, a silicone mold is crafted based on this model. The casting material is then vacuum poured into this mold, and upon curing, it replicates the original prototype. This entire procedure is referred to as the vacuum complexity model.

Vacuum Casting Service

Should you require custom machined parts featuring intricate geometries, or need end-use products delivered with utmost speed, Insight Prototype possesses the capability to efficiently navigate these demands and swiftly realize your concept.

From CNC Prototyping to Production

With 13 years of industry expertise, Insight Prototype Technology Co., Ltd. leverages its extensive manufacturing experience to offer optimal solutions for all rapid prototyping and low-volume manufacturing requirements.

Superb technology takes a short time

We have a professional technical team and have won honorary titles such as "Industry Leader" and "Excellent Enterprise of the Year". With 13 years of manufacturing experience, it will be delivered to you with scientific production techniques and processes.

Professional team quality assurance

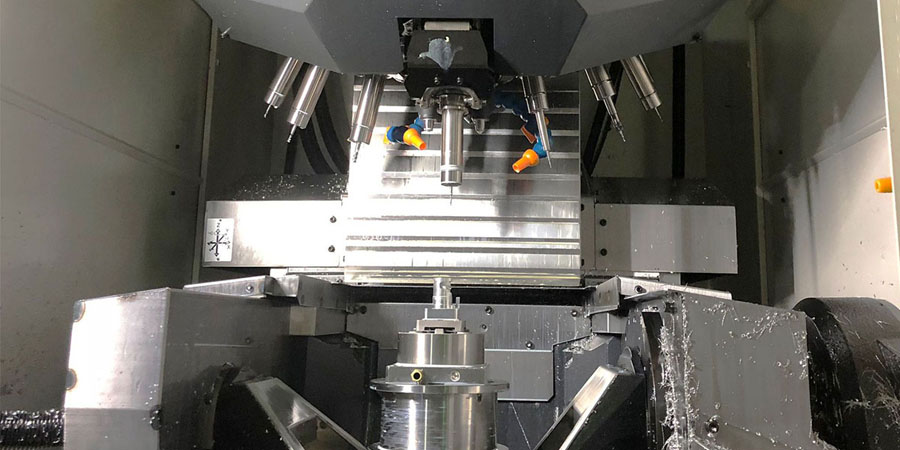

We have a professional R&D team, 5 major processing centers, 20+ high-tech talents, 40+ technical operators, and 40+ post-processing personnel. Ensure efficient and orderly completion of your order.

Have the most efficient workflow

We have the most efficient workflow, from drawing design analysis, material evaluation, machining, quality control and inspection, fast shipment of products. Reducing extra time per process minimizes lead times.

Polyurethane Vacuum Casting

The reproduction of moulds is of an incredibly high quality, with impressive detailing on the surface of the product. Little to no further treatment is needed, making it ideal for cost-effective production processes.

-

Quasi-ABS

-

PC-like

-

Polypropylene like

-

PMMA

-

Rubber

Quasi-ABS

ABS is a widely used engineering plastic that combines the rigidity of resin with the elasticity of rubber. It not only has excellent mechanical properties of toughness, hardness and rigid phase balance, but is widely used in various fields such as machinery, electrical parts, office supplies and daily necessities.

PC-like

Polycarbonate with high strength and elastic coefficient, high impact strength of the mechanical properties, suitable for automobiles, medical, aircraft, household appliances.

Polypropylene like

Polypropylene is one of the lightest resins commonly used and has excellent mechanical properties, including tensile strength, compressive strength and hardness. It is mainly used as parts of automobiles and electrical appliances, various containers, furniture, packaging materials and medical equipment

PMMA

PMMA is the best transparent polymer material at present. In the case of ultraviolet light, PMMA has better stability than polycarbonate. PMMA has the advantages of light weight and easy molding, and is widely used in instrument parts, automotive lights, optical lenses, transparent pipes and so on.

Rubber

Soft rubber materials such as polyurethane, TPU, TPE, rubber and so on. This type of material has been widely used in the field of furniture, construction, daily necessities, transportation, home appliances and so on.

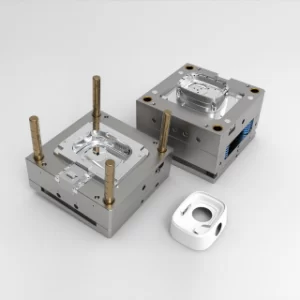

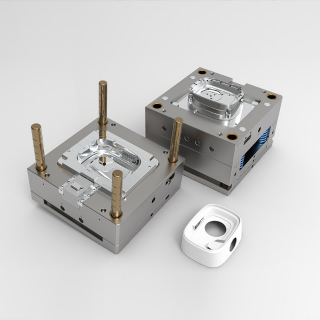

Small Molded Parts within Days

Insight prototype makes it faster, easier, and more efficient to source the custom-manufactured parts you need, precisely when and how you need them.

Surface Finishing Options For Polyurethane Vacuum Casting

To enhance the strength, durability, aesthetics, and functionality of your 3D-printed prototypes or production parts, surface finishing is essential. Consider exploring our range of custom finishing options to find one that perfectly aligns with your project's needs.

| Name | Description | Material | |

|---|---|---|---|

|

Polish | Grinding can make the surface of the product more smooth and bright, increase the quality of the product | ABS, PC, PMMA, etc N/a |

|

Oil injection | Spraying oil can make the surface of the product obtain decorative and protective effect, increase its endurance and color and sensory experience. | The material is often used for ABS

Any RAL code or Pantone number |

Surface Finishing Options For Polyurethane Vacuum Casting

Our extensive production capabilities, wide-ranging services, and stringent quality control measures provide swift, cost-efficient solutions that are geared towards enhancing your brand's value.

What Our Customers Say

The testimonials from our customers carry more significance than our own assertions. Take a moment to read what our satisfied clients have to say about how we successfully met their needs.

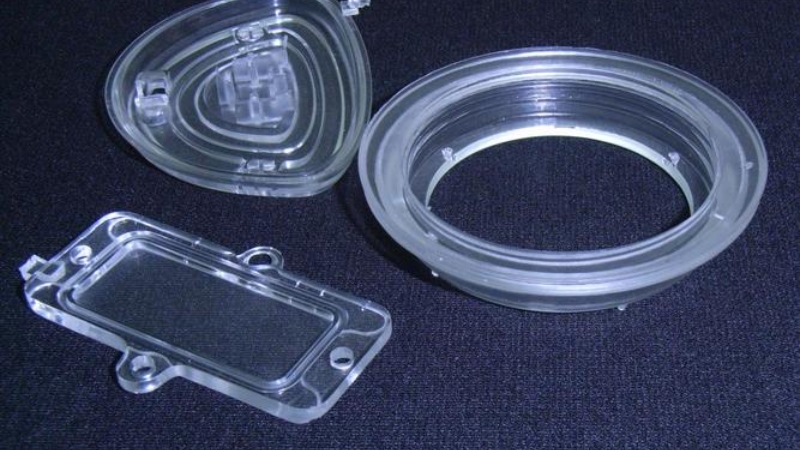

Gallery of Vacuum Casting Service Parts

Check out our extensive gallery that shows precision machined prototypes and parts from our valued customers.

About the CNC Milling Process

- Process Overview: In polyurethane vacuum casting, a master model, typically created using CNC machining or 3D printing, is used to form a silicone mold. This mold is then used to cast replicas in polyurethane.

- Material Properties: Polyurethane materials used in vacuum casting can mimic a wide range of thermoplastics, offering various levels of flexibility, hardness, and color. This makes it highly adaptable for different applications.

- High-Quality Finish: The process produces parts with excellent surface details and high-quality finishes, closely resembling injection-molded parts.

- Design Flexibility: It is ideal for complex geometries and intricate designs, allowing for undercuts and fine details that might be challenging with other manufacturing methods.

- Rapid Production: Vacuum casting is a fast method for producing small to medium quantities, making it perfect for rapid prototyping and short-run production.

- Cost-Effectiveness: It offers a cost-effective alternative to injection molding for low-volume production, especially when the high cost of mold creation for injection molding is prohibitive.

- Applications: Commonly used in automotive, medical, electronics, and consumer products industries, it is ideal for functional testing, market testing, and aesthetic prototypes.

FQA

What is Polyurethane Vacuum Casting?

What are the benefits of using this process?

How accurate is Polyurethane Vacuum Casting?

What materials can be used in Vacuum Casting?

How long does the process take?

Can it produce large parts?

Is it suitable for functional prototypes?

What industries commonly use this process?

How does it compare to injection molding?

Can you create multi-material parts?

Latest Blog Posts

Follow Insight prototype to learn more CNC industry information!