Medical equipment

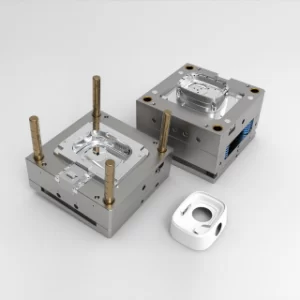

Medical treatment Vacuum injection and silicone mold that is the use of the original template, in the vacuum state to make a silicone mold, and in the vacuum state with the product material for pouring, so as to clone the same copy of the original template.

Product materials: ABS, PP, PC, PA, POM, PMMA, soft adhesive, high temperature resistant, fireproof materials and other PU materials.

Advantages: Due to the high speed and low cost, the technology greatly reduces the development cost and risk of the product, and also shorens the development cycle;

Unmatched Lead Time

Complex Geometries Support

Flexible Color Options

Material and Finishing Selection

Advantages: Due to the high speed and low cost, the technology greatly reduces the development cost and risk of the product, and also shorens the development cycle;

Suitable for medical and automotive equipment medium and small batch production needs, can be made more complex structure, uniform wall thickness, meet the functional requirements of the product.