Vacuum Casting Service

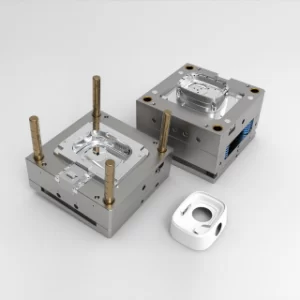

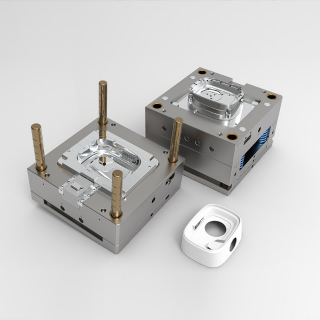

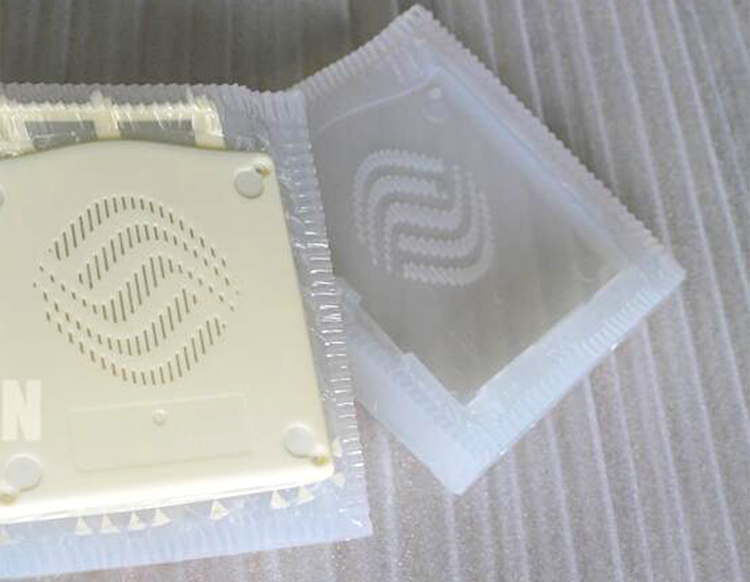

Vacuum injection molding is a technology for making replicas, also known as vacuum complex moulding. Generally, 3D printing, CNC processing and other methods are used to make a prototype first, and then use the prototype to make a silicone mold or rubber mold (currently mainly silicone molds) ), and then inject liquid resin into the mold under vacuum and harden it.

Vacuum Casting Service

Vacuum casting service is an advanced casting technology that can achieve high-precision, high-quality parts manufacturing by maintaining a certain vacuum environment during the casting process

From CNC Prototyping to Production

Insight prototype Technology Co., Ltd has 13 years of experience in the industry, and with years of manufacturing experience, provides the best solution for all rapid prototyping and low-volume manufacturing needs.

Superb technology takes a short time

We have a professional technical team and have won honorary titles such as "Industry Leader" and "Excellent Enterprise of the Year". With 13 years of manufacturing experience, it will be delivered to you with scientific production techniques and processes.

Professional team quality assurance

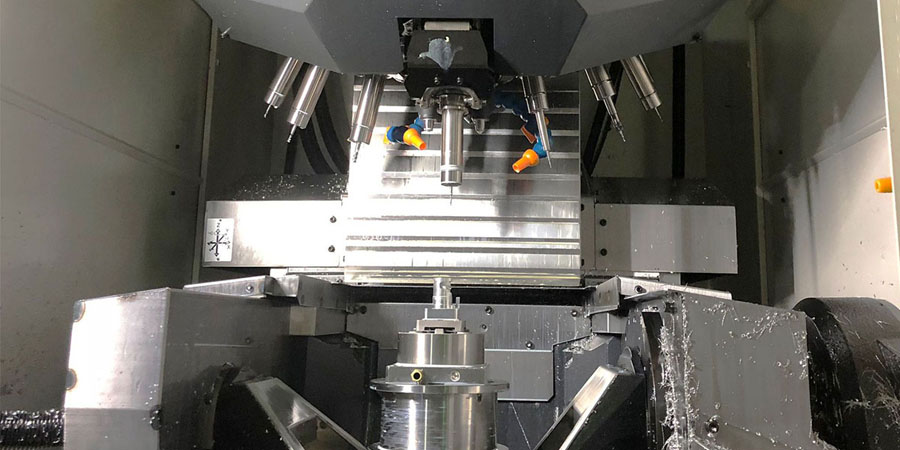

We have a professional R&D team, 5 major processing centers, 20+ high-tech talents, 40+ technical operators, and 40+ post-processing personnel. Ensure efficient and orderly completion of your order.

Have the most efficient workflow

We have the most efficient workflow, from drawing design analysis, material evaluation, machining, quality control and inspection, fast shipment of products. Reducing extra time per process minimizes lead times.

Vacuum Casting Service

Vacuum casting services are widely used in aerospace, military, automotive, medical devices, and industrial equipment, and are capable of producing high-precision, complex-shaped parts with excellent mechanical properties and surface quality

-

Quasi-ABS

-

PC-like

-

Polypropylene like

-

PMMA

-

Rubber

Quasi-ABS

ABS is a widely used engineering plastic that combines the rigidity of resin with the elasticity of rubber. It not only has excellent mechanical properties of toughness, hardness and rigid phase balance, but is widely used in various fields such as machinery, electrical parts, office supplies and daily necessities.

PC-like

Polycarbonate with high strength and elastic coefficient, high impact strength of the mechanical properties, suitable for automobiles, medical, aircraft, household appliances.

Polypropylene like

Polypropylene is one of the lightest resins commonly used and has excellent mechanical properties, including tensile strength, compressive strength and hardness. It is mainly used as parts of automobiles and electrical appliances, various containers, furniture, packaging materials and medical equipment

PMMA

PMMA is the best transparent polymer material at present. In the case of ultraviolet light, PMMA has better stability than polycarbonate. PMMA has the advantages of light weight and easy molding, and is widely used in instrument parts, automotive lights, optical lenses, transparent pipes and so on.

Rubber

Soft rubber materials such as polyurethane, TPU, TPE, rubber and so on. This type of material has been widely used in the field of furniture, construction, daily necessities, transportation, home appliances and so on.

Small Molded Parts within Days

Insight prototype makes it faster, easier, and more efficient to source the custom-manufactured parts you need, precisely when and how you need them.

Vacuum Casting Service

A numebr of materials can be used in Vacuum Casting Service, giving you various of options to complete rapid prototyping to production runs of custom complex parts. For your manufacturing needs, we provide instant quotatios of 100+ metals and plastics, and even you can compare prices for different machining materials.

| Name | Description | Material | |

|---|---|---|---|

|

Polish | Grinding can make the surface of the product more smooth and bright, increase the quality of the product | ABS, PC, PMMA and all metals |

|

Painting | Painting involves spraying a layer of paint onto the surface of thepart. Colors can be matched to a Pantone color number of thecustomer' s choosing, while finishes range from matte to gloss tometallic. | The material is often used for ABS

Any RAL code or Pantone number |

Vacuum Casting Service

Our robust production capabilities, comprehensive services, and strong quality control offer fast and cost-effective solutions that will help you improve your brand.

What Our Customers Say

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements.

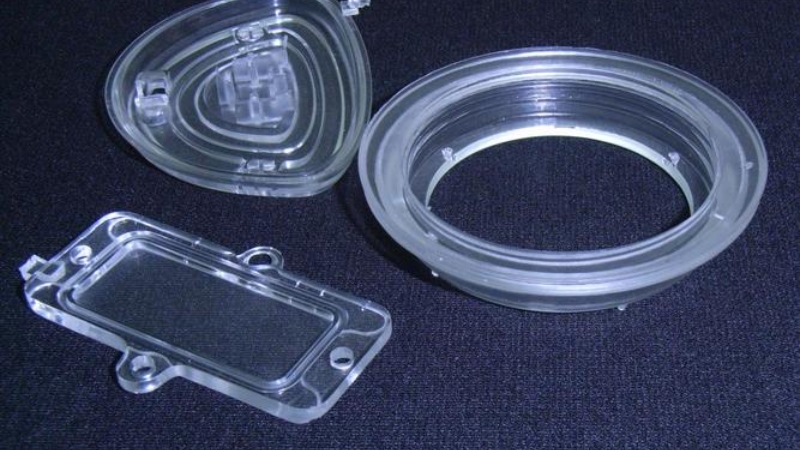

Gallery of Vacuum Casting Service Parts

Check out our extensive gallery that shows precision machined prototypes and parts from our valued customers.

About the CNC Milling Process

With milling, the stock that the part will be cut from is usually a six-sided bar or sheet of material (though it can be also a cylindrical rodi). This stock is fixtured to the bed of the machine and the features of the part are cut using a rotating tool such as a drill or endmill.

Frequently Asked Questions

What are the advantages of CNC machining?

What are the different types of machining processes?

What industries use CNC machinery?

What are standard machining tolerances?

Latest Blog Posts

Follow Insight prototype to learn more CNC industry information!