Rapid CNC Machining Service

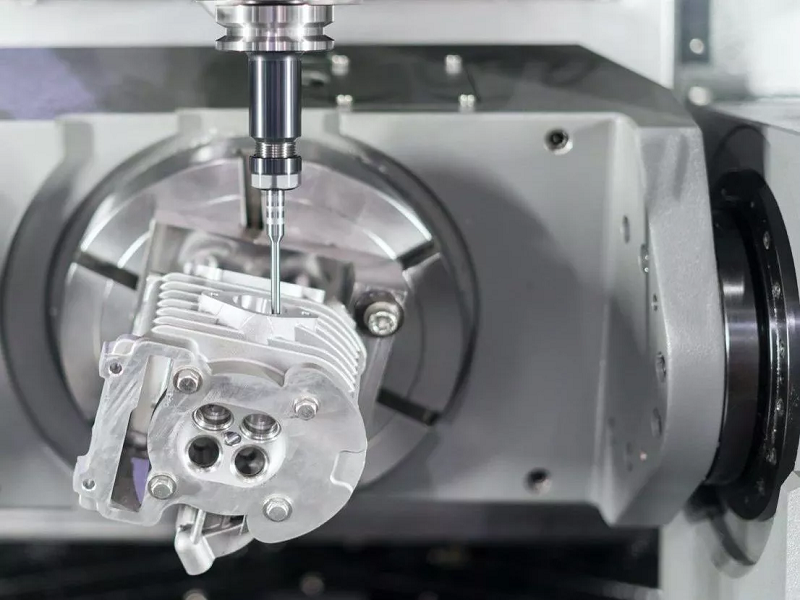

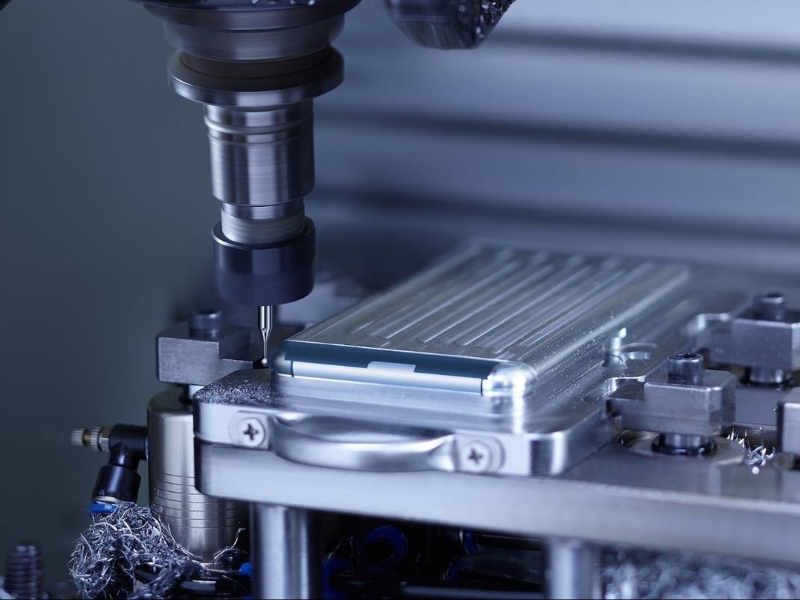

For those requiring custom-machined parts with intricate designs or end-use products delivered swiftly, our capabilities are designed to swiftly bring your concepts to life. With over 15 multi-axis CNC machines, including 3, 4, and 5-axis models, and a selection of more than 100 materials and finishes, we ensure a rapid turnaround and high-quality output for both one-off prototypes and full-scale production parts.

Rapid CNC Machining Service

if you need custom machined parts with complex geometries, or get end-use products in the shortest possible time.

Insight prototype is good enough to break through al of that and achieve your idea immediately.

From CNC Prototyping to Production

Insight prototype Technology Co., Ltd has 13 years of experience in the industry, and with years of manufacturing experience, provides the best solution for all rapid prototyping and low-volume manufacturing needs.

Superb technology takes a short time

We have a professional technical team and have won honorary titles such as "Industry Leader" and "Excellent Enterprise of the Year". With 13 years of manufacturing experience, it will be delivered to you with scientific production techniques and processes.

Professional team quality assurance

We have a professional R&D team, 5 major processing centers, 20+ high-tech talents, 40+ technical operators, and 40+ post-processing personnel. Ensure efficient and orderly completion of your order.

Have the most efficient workflow

We have the most efficient workflow, from drawing design analysis, material evaluation, machining, quality control and inspection, fast shipment of products. Reducing extra time per process minimizes lead times.

Rapid CNC Machining Service

Import the prototype design document into the 3D processing software, and the programmer can write the processing program at the lowest cost and fastest processing speed

-

Aluminium alloy

-

Stainless steel

-

Orichalcum

-

Titanium

-

Plastic

Aluminium alloy

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

- Lead time:<7 days

- Tolerance: +/-0.01mm

Stainless steel

In many industrial production processes, stainless steel can provide satisfactory corrosion resistance and other excellent characteristics. The performance advantages of stainless steel: high strength, high temperature resistance, corrosion resistance, beautiful surface and so on; It can be applied to many fields.

- Lead time:<7 days

- How: = + / - 0.02 mm

Orichalcum

The mechanical properties and wear resistance of brass are very good, and can be used to manufacture precision instruments and parts of ships. In general, the amount of precision copper parts such as auto parts, medical parts, electrical parts is more.

- Lead time:<7 days

- How: = + / - 0.05 mm

Titanium

Titanium products have the advantages of light quality, high specific strength, good corrosion resistance, etc., so it is widely used in the automobile, aircraft, medical industry, the use of titanium alloy is mostly engine system software.

- Lead time:<7 days

- How: = + / - 0.02 mm

Plastic

With the rapid development of the plastic industry and the continuous improvement of plastic properties, plastic parts have been more widely used, plastic parts are replacing traditional metal parts in different fields, a reasonable design of plastic parts can often replace a number of traditional metal parts, so as to achieve the purpose of simplifying product structure and saving manufacturing costs.

- Lead time:<7 days

- How: = + / - 0.1 mm

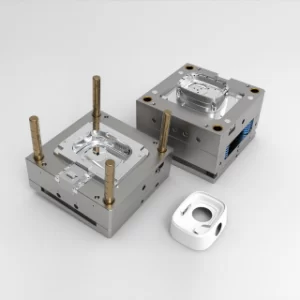

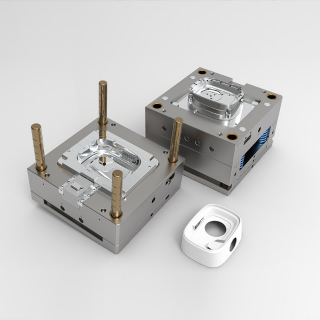

Small Molded Parts within Days

Insight prototype makes it faster, easier, and more efficient to source the custom-manufactured parts you need, precisely when and how you need them.

Surface Finishing Options For Rapid CNC Machining Service

Our company has 11 years of experience in CNC prototype processing, and has accumulated rich experience in various fields including automobiles, household appliances, medical care, intelligence, etc., and can produce prototypes quickly, efficiently, and at low cost.

| Name | Description | Material | |

|---|---|---|---|

|

Polishing | Polishing reduces the surface roughness of the workpiece to obtain a bright and smooth surface processing method. Is the use of polishing tools and abrasive particles or other polishing media to modify the surface of the workpiece. | Acrylic, metal material |

|

Screen printing & pad printing | Screen printing process is also known as screen printing process, screen printing is a main printing method in hole printing, is a printing process technology with very distinctive printing characteristics and imaging process. Because of the flexibility and wide adaptability of screen printing, more vivid expression of creative design concepts, sometimes, such a choice is really a good idea. |

Surface Finishing Options For Rapid CNC Machining Service

Our robust production capabilities, comprehensive services, and strong quality control offer fast and cost-effective solutions that will help you improve your brand.

What Our Customers Say

The feedback from our customers holds more weight than any claim we make – take a look at the testimonials from our satisfied clients to see how we've successfully met their needs.

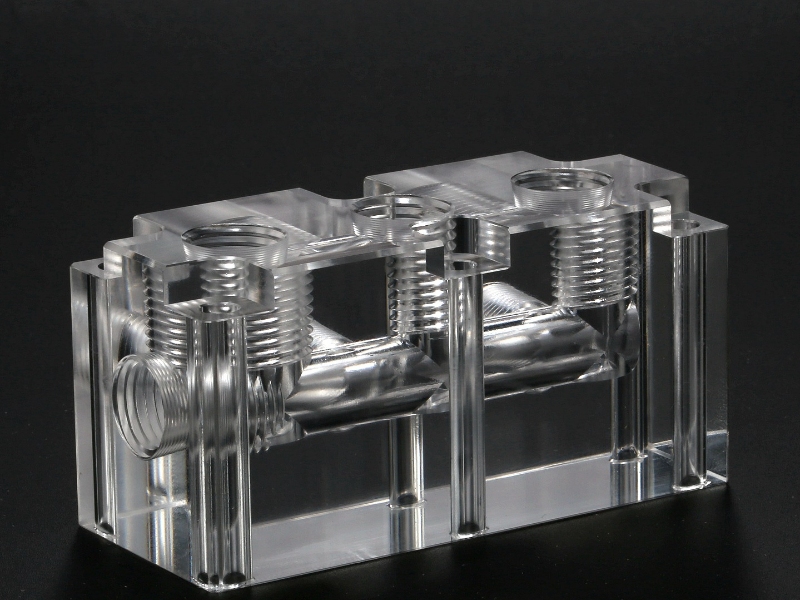

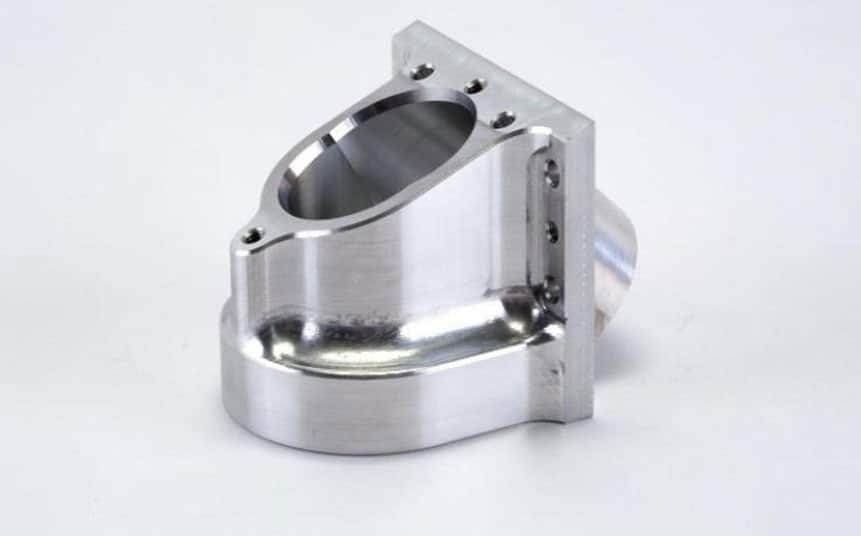

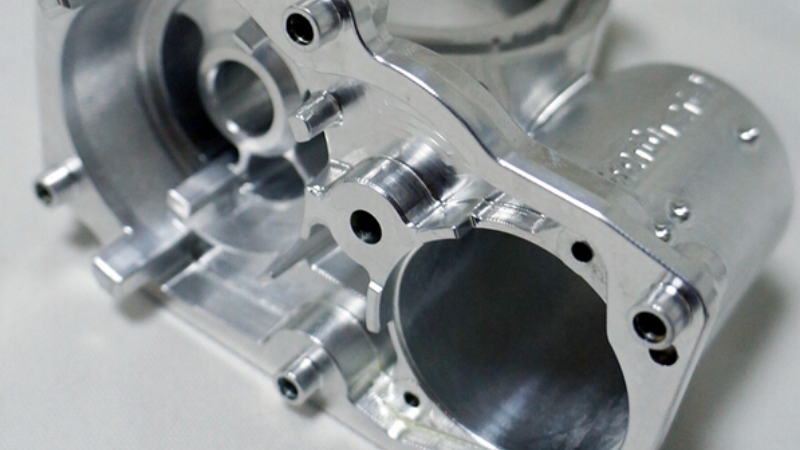

Gallery of CNC Machined Parts

Check out our extensive gallery that shows precision machined prototypes and parts from our valued customers.

Product Description for Rapid CNC Machining Service:

Rapid CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

Product Description for Rapid CNC Machining Service:

- Speed and Efficiency: Rapid CNC machining is known for its speed and efficiency in producing parts and components. This service can significantly reduce the turnaround time from design to production.

- Precision and Accuracy: CNC machining offers high precision and accuracy in manufacturing parts. It is ideal for creating complex shapes with tight tolerances.

- Versatility: This service can work with a variety of materials, including metals, plastics, and composites, making it suitable for a wide range of industries and applications.

- Customization: Rapid CNC machining allows for high levels of customization. It can produce bespoke parts tailored to specific requirements.

- Automated Production: The automation aspect of CNC machining minimizes human error and ensures consistent quality across all produced parts.

- Scalability: This service is scalable, suitable for both small batch production and large-scale manufacturing.

- Cost-Effective: Although the initial setup cost can be high, the overall cost-effectiveness of CNC machining is notable, especially for high-volume production runs.

- Design Integration: CNC machining services often integrate seamlessly with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, streamlining the design and production process.

Frequently Asked Questions

What are the advantages of CNC machining?

What are the different types of machining processes?

What industries use CNC machinery?

What are standard machining tolerances?

Latest Blog Posts

Follow Insight prototype to learn more CNC industry information!