Custom Online CNC Machining Services

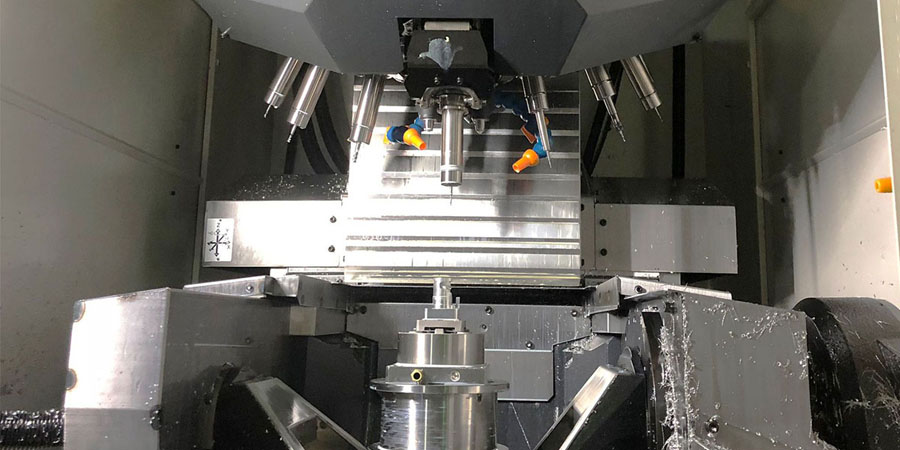

CNC machining involves the use of CNC tools and machines, which are operated and controlled through CNC machining language, typically G code. This language directs the CNC machine tool to specific Cartesian positional coordinates while managing aspects like tool feed speed, spindle speed, and additional functions such as tool changing and coolant application.

CNC Machining Services

Receive immediate pricing for your metal or plastic projects, whether they are prototypes or production parts, using our online CNC machining services. Select from over 40 materials and more than 10 surface finishes, all backed by ISO 9001:2015 and ISO 13485 certifications.

From CNC Prototyping to Production

Insight prototype's custom CNC services cater to engineers, product developers, and designers in need of prototyping and low-volume production. We handle everything from straightforward to complex designs, maintaining tight tolerances, all within our ISO 9001-certified CNC machine shops. Our quick CNC machining processes guarantee the delivery of quality custom-machined parts, with some orders fulfilled in as little as 1 day.

Superb technology takes a short time

We have a professional technical team and have won honorary titles such as "Industry Leader" and "Excellent Enterprise of the Year". With 13 years of manufacturing experience, it will be delivered to you with scientific production techniques and processes.

Professional team quality assurance

We have a professional R&D team, 5 major processing centers, 20+ high-tech talents, 40+ technical operators, and 40+ post-processing personnel. Ensure efficient and orderly completion of your order.

Have the most efficient workflow

We have the most efficient workflow, from drawing design analysis, material evaluation, machining, quality control and inspection, fast shipment of products. Reducing extra time per process minimizes lead times.

Materials for Custom CNC Machining Parts

CNC machines accommodate a wide array of materials, offering diverse options for everything from rapid prototyping to producing custom complex parts. To address your manufacturing requirements, we offer immediate quotes for over 100 types of metals and plastics, allowing you to compare costs across different machining materials efficiently.

-

Aluminium alloy

-

Stainless steel

-

Orichalcum

-

Titanium

-

Plastic

Aluminium alloy

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

- Lead time:<7 days

- Tolerance: +/-0.01mm

Stainless steel

In many industrial production processes, stainless steel can provide satisfactory corrosion resistance and other excellent characteristics. The performance advantages of stainless steel: high strength, high temperature resistance, corrosion resistance, beautiful surface and so on; It can be applied to many fields.

- Lead time:<7 days

- How: = + / - 0.02 mm

Orichalcum

The mechanical properties and wear resistance of brass are very good, and can be used to manufacture precision instruments and parts of ships. In general, the amount of precision copper parts such as auto parts, medical parts, electrical parts is more.

- Lead time:<7 days

- How: = + / - 0.05 mm

Titanium

Titanium products have the advantages of light quality, high specific strength, good corrosion resistance, etc., so it is widely used in the automobile, aircraft, medical industry, the use of titanium alloy is mostly engine system software.

- Lead time:<7 days

- How: = + / - 0.02 mm

Plastic

With the rapid development of the plastic industry and the continuous improvement of plastic properties, plastic parts have been more widely used, plastic parts are replacing traditional metal parts in different fields, a reasonable design of plastic parts can often replace a number of traditional metal parts, so as to achieve the purpose of simplifying product structure and saving manufacturing costs.

- Lead time:<7 days

- How: = + / - 0.1 mm

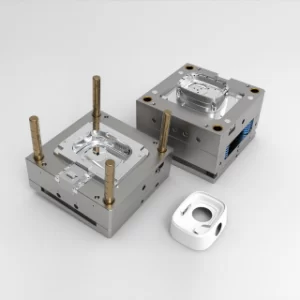

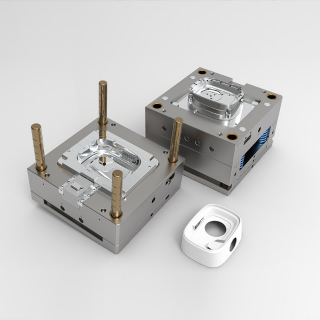

Small Molded Parts within Days

Insight prototype makes it faster, easier, and more efficient to source the custom-manufactured parts you need, precisely when and how you need them.

CNC Machining Materials

CNC machines are compatible with numerous materials, providing a range of options for rapid prototyping and the production of intricate custom parts. We cater to your manufacturing needs by offering on-the-spot quotes for over 100 metals and plastics, enabling you to conveniently compare prices across various machining materials

| Name | Description | Material | |

|---|---|---|---|

|

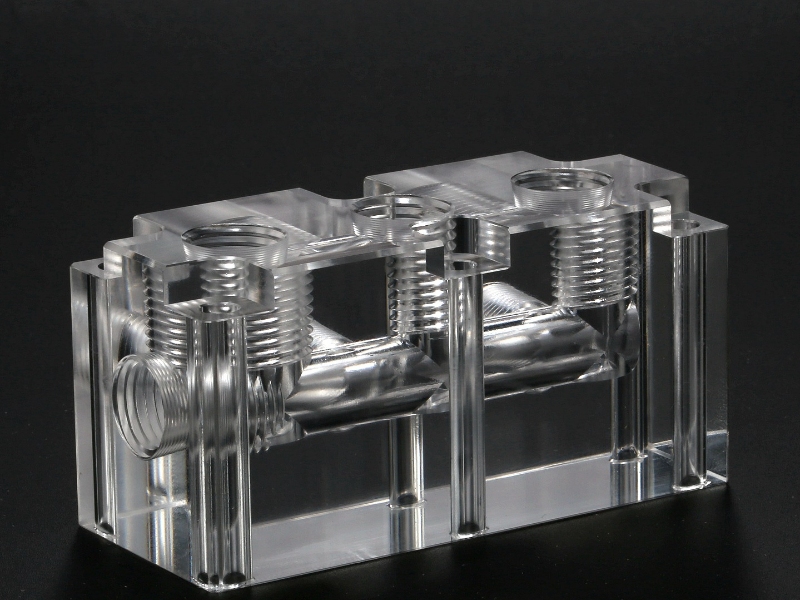

Polishing | Polishing reduces the surface roughness of the workpiece to obtain a bright and smooth surface processing method. Is the use of polishing tools and abrasive particles or other polishing media to modify the surface of the workpiece. | Acrylic, metal material |

|

Screen printing & pad printing | Screen printing process is also known as screen printing process, screen printing is a main printing method in hole printing, is a printing process technology with very distinctive printing characteristics and imaging process. Because of the flexibility and wide adaptability of screen printing, more vivid expression of creative design concepts, sometimes, such a choice is really a good idea. |

CNC Machining Materials

Our extensive production capabilities, wide-ranging services, and stringent quality control measures provide swift and economical solutions designed to elevate your brand's standing.

What Our Customers Say

The testimonials from our clients carry more weight than our own statements. We invite you to read the feedback from our satisfied customers and see how we've successfully met their needs.

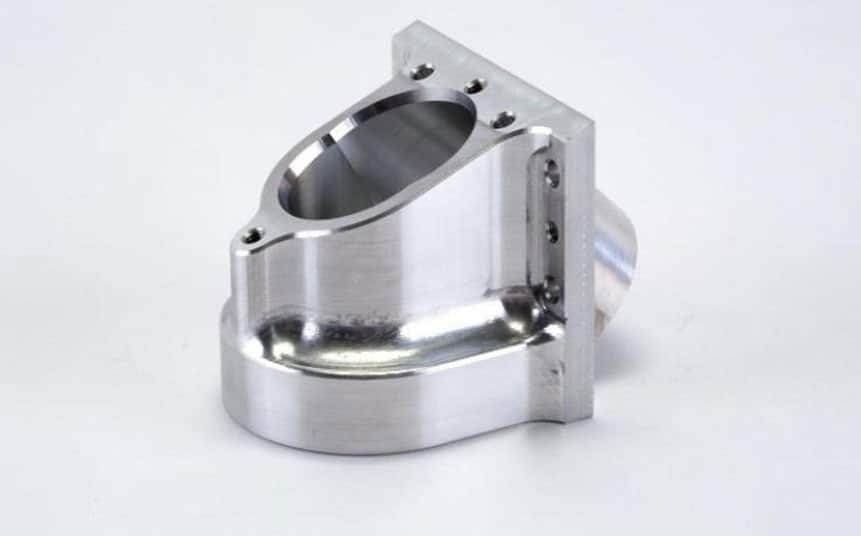

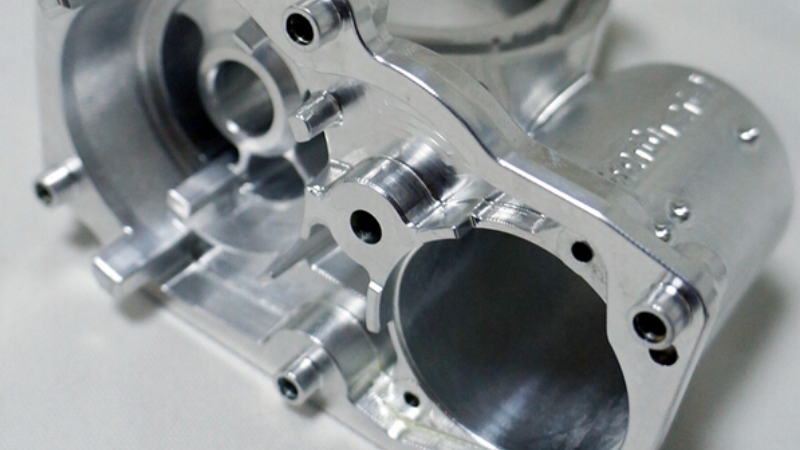

Gallery of CNC Machined Parts

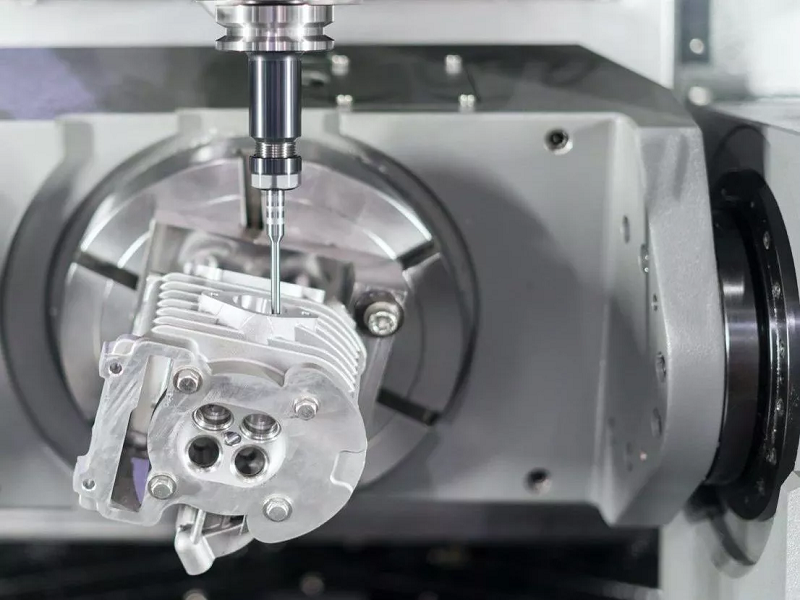

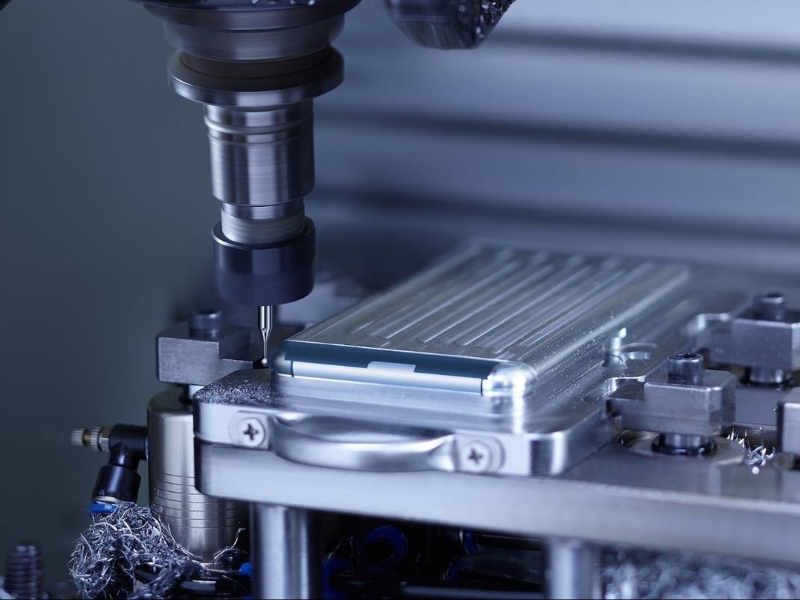

About the CNC Milling Process

With milling, the stock that the part will be cut from is usually a six-sided bar or sheet of material (though it can be also a cylindrical rodi). This stock is fixtured to the bed of the machine and the features of the part are cut using a rotating tool such as a drill or endmill.

FAQs About insightprototype CNC Services

What is CNC Machining?

What materials can be used in CNC Machining?

What industries benefit from CNC Machining?

How accurate is CNC Machining?

Can CNC Machining produce complex parts?

What are the types of CNC Machining?

How does CNC Machining compare to 3D Printing?

Is CNC Machining suitable for prototyping?

What is the typical lead time for CNC Machined parts?

Can I customize my CNC Machining project?

Latest Blog Posts

Follow Insight prototype to learn more CNC industry information!