Custom Online Sheet Metal Fabrication Services

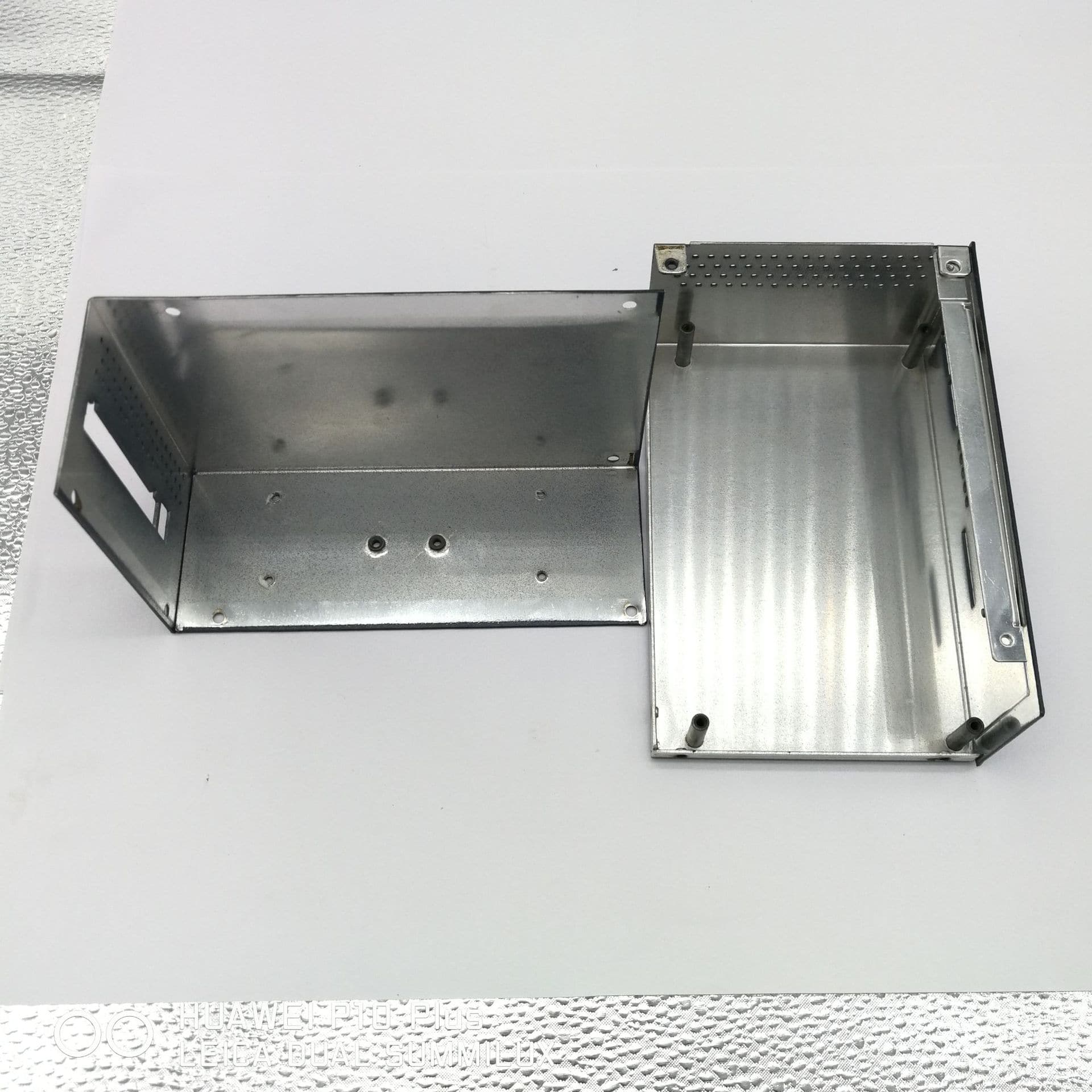

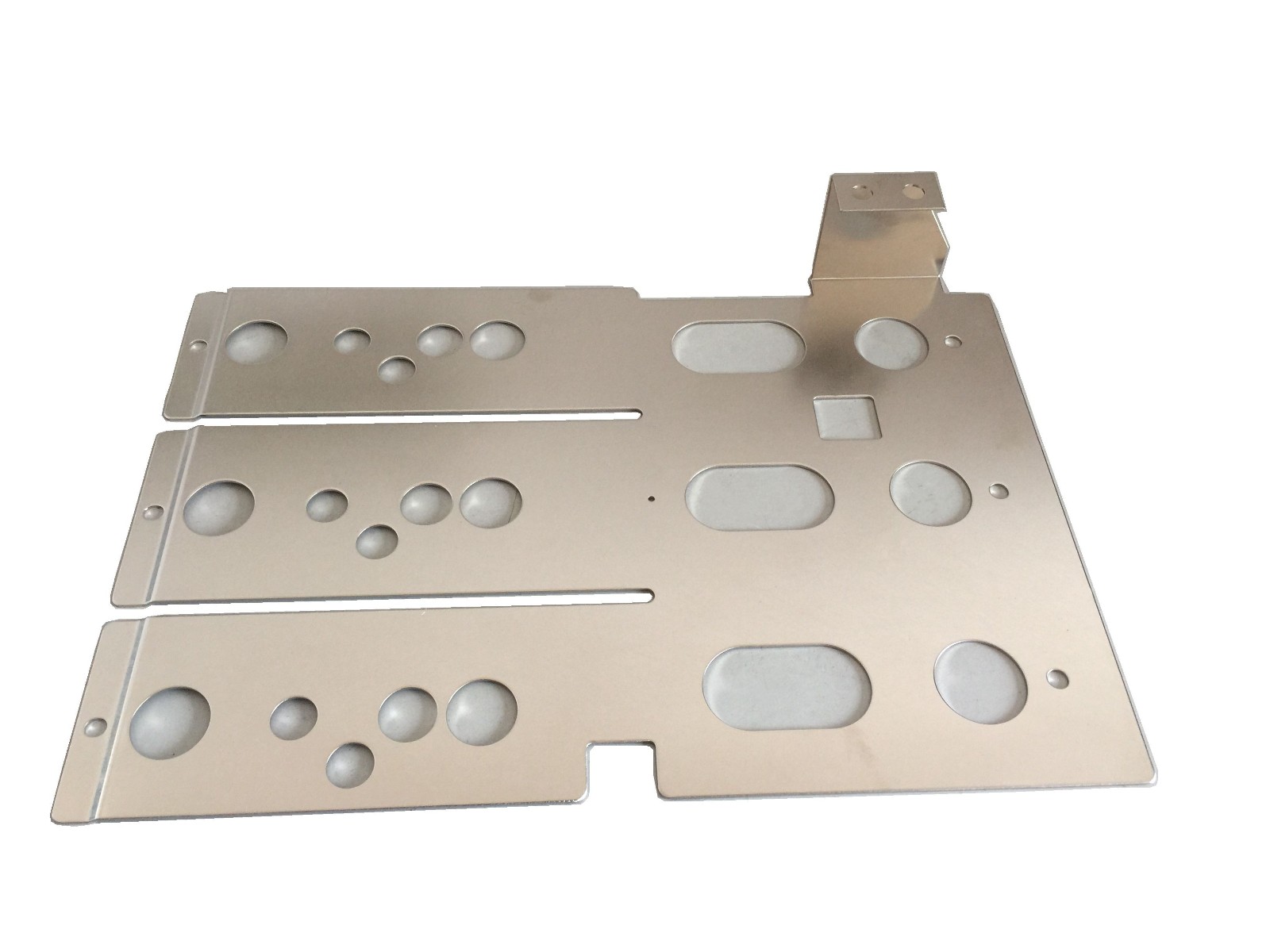

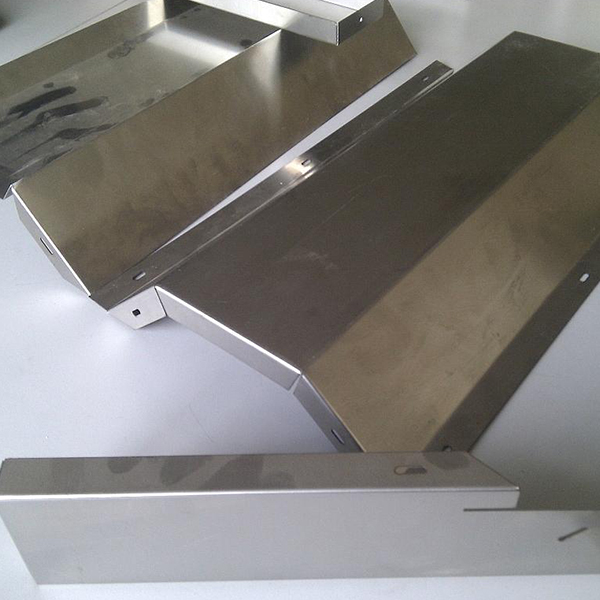

Sheet metal processing is a key technology that sheet metal technicians need to master, and it is also an important process for forming sheet metal products. Sheet metal processing includes traditional cutting, punching, bending and forming methods and process parameters

Sheet Metal Fabrication Services

if you need custom machined parts with complex geometries, or get end-use products in the shortest possible time.

Insight prototype is good enough to break through al of that and achieve your idea immediately.

From CNC Prototyping to Production

insight prototype Technology Co., Ltd has 13 years of experience in the industry, and with years of manufacturing experience, provides the best solution for all rapid prototyping and low-volume manufacturing needs.

Superb technology takes a short time

We have a professional technical team and have won honorary titles such as "Industry Leader" and "Excellent Enterprise of the Year". With 13 years of manufacturing experience, it will be delivered to you with scientific production techniques and processes.

Professional team quality assurance

We have a professional R&D team, 5 major processing centers, 20+ high-tech talents, 40+ technical operators, and 40+ post-processing personnel. Ensure efficient and orderly completion of your order.

Have the most efficient workflow

We have the most efficient workflow, from drawing design analysis, material evaluation, machining, quality control and inspection, fast shipment of products. Reducing extra time per process minimizes lead times.

Sheet Metal Fabrication Materials

-

Aluminum

-

Copper

-

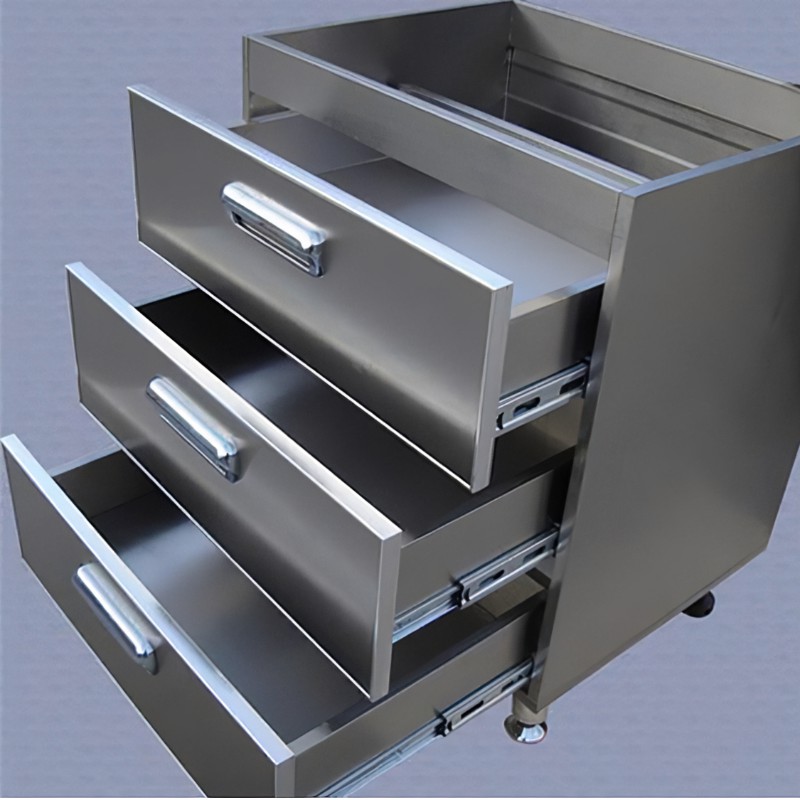

Stainless Steel

-

Titanium

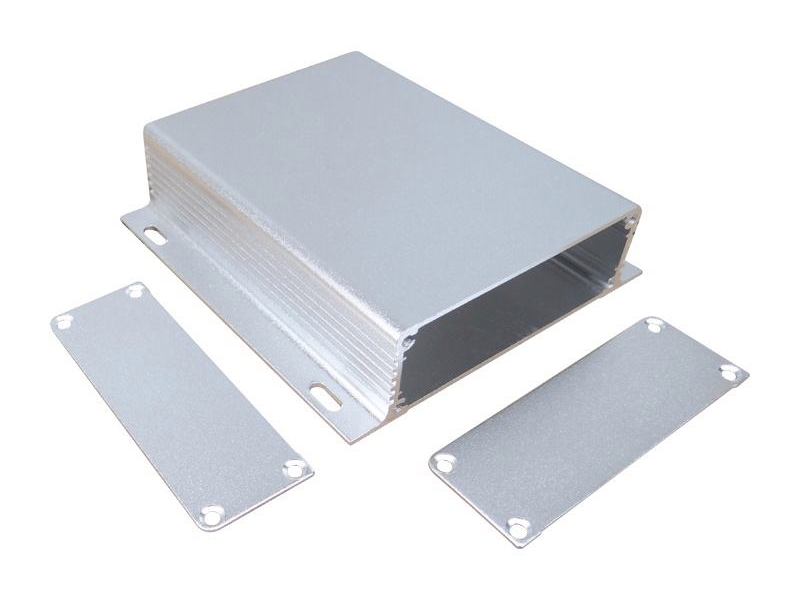

Aluminum

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

- Mill Lead Time: As fast as 7 days

- Finish Options: Media blasting, Tumbling

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

- Mill Lead Time: As fast as 7 days

- Finish Options: Media blasting, Tumbling

Stainless Steel

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

- Mill Lead Time: As fast as 7 days

- Finish Options: Media blasting, Tumbling

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

- Mill Lead Time: As fast as 7 days

- Finish Options: Media blasting, Tumbling

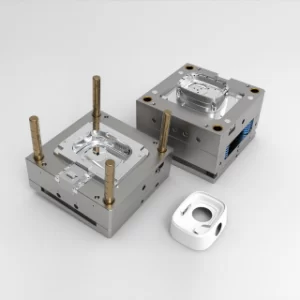

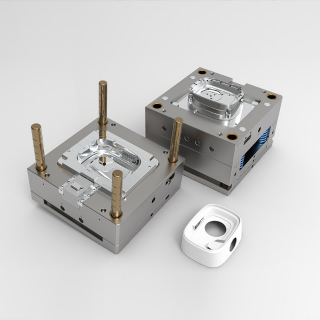

Small Molded Parts within Days

Insight prototype makes it faster, easier, and more efficient to source the custom-manufactured parts you need, precisely when and how you need them.

Sheet Metal Fabrication Standards

| Name | Description | Material | |

|---|---|---|---|

|

Powder spraying | The advantage of powder spraying process, also known as powder coating, is that its coating has high wear resistance, corrosion resistance and weather resistance, which can protect the surface of items from damage in harsh environments. In addition, the powder spraying process also has the advantages of uniform coating thickness, bright color and high gloss, which can provide a beautiful appearance for the surface of the article. | Stainless steel |

|

oxidation | Anodizing can form an oxide film protective layer on the surface of aluminum alloy die-casting parts, thereby increasing the density and corrosion resistance of die-casting parts. Anodizing can not only obtain a high transparency oxide film, but also dye a variety of bright colors with fuel. Hard anodizing not only has high hardness and thickness, but also has low roughness. It can greatly improve its wear resistance. |

Aluminium alloy |

Sheet Metal Fabrication Standards

Our robust production capabilities, comprehensive services, and strong quality control offer fast and cost-effective solutions that will help you improve your brand.

What Our Customers Say

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements.

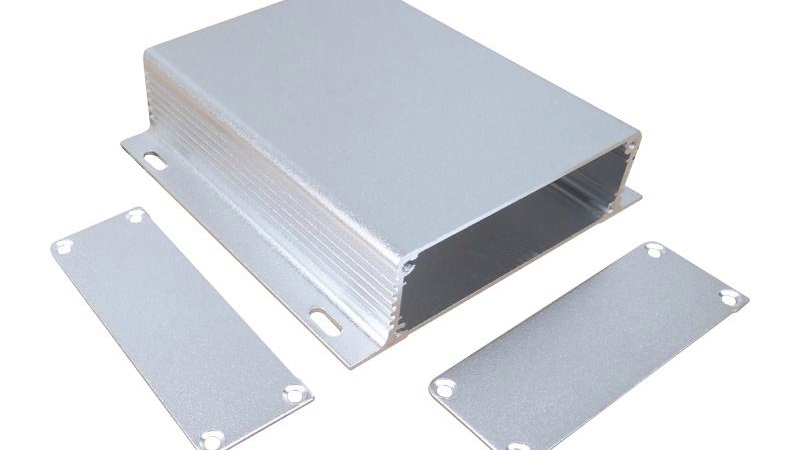

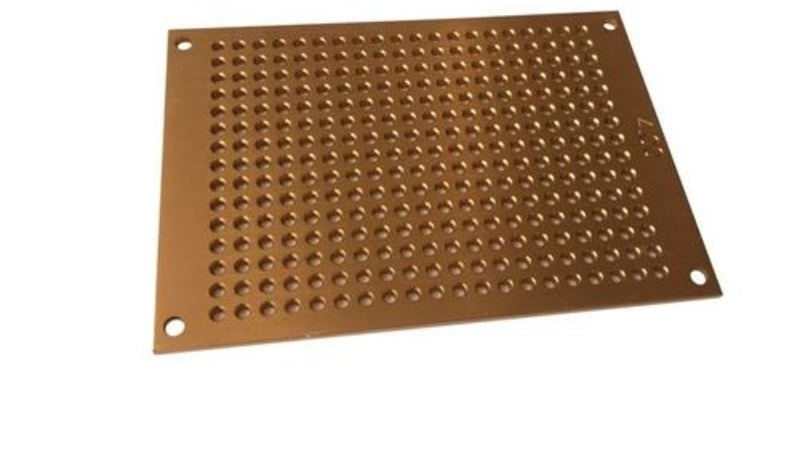

Gallery of Sheet Metal Fabrication Parts

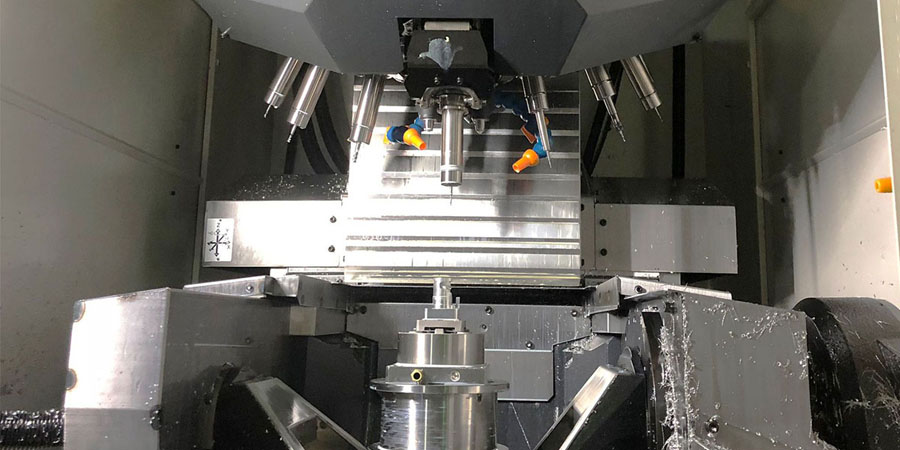

About the CNC Milling Process

With milling, the stock that the part will be cut from is usually a six-sided bar or sheet of material (though it can be also a cylindrical rodi). This stock is fixtured to the bed of the machine and the features of the part are cut using a rotating tool such as a drill or endmill.

Frequently Asked Questions

What are the advantages of CNC machining?

What are the different types of machining processes?

What industries use CNC machinery?

What are standard machining tolerances?

Latest Blog Posts

Follow insight prototype to learn more CNC industry information!