Exploring the Future Trends of Online CNC Quote: What's Next?

Unveil the impactful potential of online CNC quote, driving manufacturing efficiency, precision, and transparency. Navigate through future trends, challenges, and opportunities, while understanding the influence of emerging technologies on CNC machining quote. Delve into the pivotal aspects of accuracy, transparency, and customer experience for refining and optimizing the online quoting process.

Understanding the Significance of CNC Machining

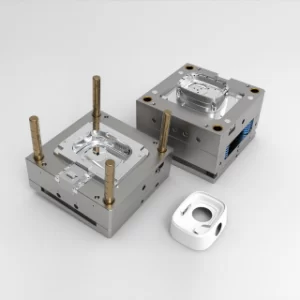

CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls to operate and manipulate machine tools, producing intricate and precise components from various materials. From aerospace to automotive industries, CNC machining plays a vital role in creating parts with high levels of accuracy and repeatability.

1.1 Why Online Quotes Matter

In the dynamic environment of manufacturing, time is of the essence. Online CNC quote offers a streamlined approach to obtaining pricing and lead time information, eliminating the delays associated with traditional quoting methods. This efficiency translates into faster decision-making and reduced time-to-market for products.

1.2 The Impact on Business Operations

The adoption of online CNC quote has far-reaching implications for businesses. By expediting the quoting process, manufacturers can allocate resources more effectively, optimize production schedules, and respond swiftly to customer demands. This agility enhances competitiveness and strengthens customer relationships, driving overall business growth.

Key Elements of an Effective Online CNC Quote System

2.1 Essential Components

A robust online CNC quote system encompasses various essential components, including detailed part specifications, material selection, quantity requirements, and lead time expectations. By providing comprehensive information upfront, suppliers like Insight Prototype Co., Ltd., can accurately assess project requirements and deliver tailored solutions.

2.2 Clear Communication Channels

Effective communication is paramount in ensuring the accuracy and success of CNC machining projects. Online platforms facilitate seamless interaction between customers and suppliers, enabling real-time collaboration, customization, and revisions as needed. Clear communication channels foster transparency and trust, laying the foundation for successful partnerships.

2.3 Instant Pricing Mechanisms

Gone are the days of waiting for manual calculations and quotes. With instant pricing mechanisms integrated into online platforms, customers can obtain accurate cost estimates with just a few clicks. This immediacy empowers decision-makers to evaluate project feasibility and budget considerations promptly, driving efficiency and informed decision-making.

Maximizing Efficiency with Automated Quoting Systems

3.1 Introduction to Automation

Automated quoting software represents a paradigm shift in CNC machining operations. By leveraging advanced algorithms and data analytics, these systems streamline the entire quoting process, from initial inquiry to final pricing. Insight Prototype Co., Ltd., embraces automation to enhance efficiency and deliver superior customer experiences.

3.2 Case Studies

The benefits of automated quoting are tangible and compelling. Case studies demonstrate significant time and cost savings achieved through automation, highlighting its transformative impact on manufacturing workflows. By eliminating manual interventions and reducing error margins, automated systems drive operational excellence and competitiveness.

3.3 Tips for Implementation

Implementing automated quoting systems requires careful planning and execution. Insight Prototype Co., Ltd., offers valuable insights and tips for integrating automation into existing workflows seamlessly. From software selection to staff training, proper implementation ensures maximum efficiency gains and a smooth transition to automated quoting processes.

Ensuring Accuracy in CNC Machining Quotes

4.1 Avoiding Common Pitfalls

Manual quoting processes are prone to errors due to human oversight, misinterpretation of specifications, and inconsistent pricing calculations. These pitfalls can lead to inaccurate quotes, causing delays, budget overruns, and customer dissatisfaction. Insight Prototype Co., Ltd., recognizes the importance of addressing these challenges to deliver reliable and precise quotes to its customers.

4.2 Enhancing Precision with Digital Tools

Digital tools play a pivotal role in improving the accuracy of CNC machining quotes. By automating calculations, standardizing processes, and cross-referencing data, these tools minimize the risk of human error. Insight Prototype Co., Ltd., leverages cutting-edge software to ensure consistency and reliability in its quoting processes, ultimately enhancing precision and customer satisfaction.

4.3 Strategies for Verification

To uphold the highest standards of accuracy, strategies for verifying quote accuracy are essential. Insight Prototype Co., Ltd., implements rigorous quality control measures, including double-checking specifications, reviewing pricing algorithms, and conducting internal audits. By proactively identifying and rectifying discrepancies, the company maintains its reputation for delivering precise and dependable CNC machining quotes.

Optimizing Customer Experience through Transparent Quoting

5.1 Importance of Transparency

Transparency in quoting is paramount for building trust and fostering long-term relationships with customers. Insight Prototype Co., Ltd., prioritizes transparency by providing clear and detailed breakdowns of costs, timelines, and project milestones. By openly communicating pricing factors and production processes, the company ensures that customers are well-informed and confident in their decision-making.

5.2 Detailed Breakdowns

Customers appreciate transparency when it comes to understanding the factors that influence pricing and lead times. Insight Prototype Co., Ltd., goes the extra mile to provide comprehensive breakdowns of costs, including material expenses, labor costs, and overheads. Additionally, the company outlines realistic timelines and milestones, setting clear expectations and minimizing surprises throughout the manufacturing process.

5.3 Utilizing Online Platforms

Online platforms offer unparalleled convenience and accessibility for tracking quotes and project status updates in real time. Insight Prototype Co., Ltd., leverages advanced online systems to provide customers with instant access to their quotes, order progress, and production schedules. By facilitating seamless communication and transparency, these platforms enhance the overall customer experience and satisfaction.

Future Trends in Online CNC Quoting

6.1 Exploring Emerging Technologies

The future of CNC machining quotes is shaped by emerging technologies that enable greater automation, efficiency, and predictive capabilities. Insight Prototype Co., Ltd., remains at the forefront of innovation by exploring cutting-edge solutions such as predictive analytics and AI-driven quoting systems. These technologies have the potential to revolutionize the quoting process, offering real-time insights and predictive modeling to optimize pricing and production decisions.

6.2 Challenges and Opportunities

While advanced technologies present exciting opportunities for improving CNC machining quotes, they also pose challenges in terms of implementation and adoption. Insight Prototype Co., Ltd., remains vigilant in navigating these complexities, balancing the benefits of innovation with the need for reliability and accuracy. By staying agile and responsive to industry trends, the company continues to deliver exceptional value to its customers in the ever-evolving landscape of online CNC quoting.

Conclusion

In the ever-evolving landscape of manufacturing, embracing innovation is essential for staying competitive. Online CNC quotes represent a pivotal advancement in streamlining operations, enhancing efficiency, and delivering superior customer experiences. As industry leaders like Insight Prototype Co., Ltd., continue to harness the power of technology, the future of CNC machining looks brighter than ever before.