Application of CNC: How Does it Accelerate Product Development?

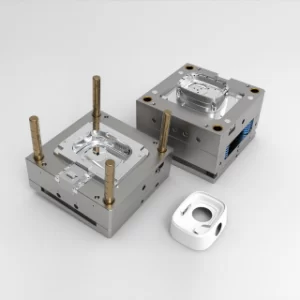

Within the manufacturing domain, CNC machining has revolutionized operations by delivering unmatched precision, efficiency, and adaptability. At the forefront of this transformation is Insight Prototype Co., Ltd, renowned for its exceptional Application of CNC services. Catering to a broad spectrum of industries including automotive, robotics, renewable energy, furniture, home appliances, and medical equipment, Insight Prototype tailors its solutions to meet the distinct demands of each sector. Let's delve into how CNC machining effectively meets the precise needs of these industries and how Insight Prototype consistently delivers inventive solutions.

CNC Machining in the Automotive Sector: Precision at Every Turn

1. Engine Components: Within the automotive industry, precision is paramount, especially when it comes to engine components. CNC machining enables the fabrication of intricate parts with tight tolerances, ensuring optimal performance and reliability.

2. Chassis Parts: The structural integrity of vehicles relies on precisely manufactured chassis parts. CNC machining allows for the production of complex geometries and lightweight components that enhance vehicle safety and performance.

3. Prototyping: Rapid prototyping is essential for automotive manufacturers to test new designs and concepts efficiently. Insight Prototype's CNC machining services offer quick turnaround times for prototype development, allowing for faster iterations and improvements.

Empowering Intelligent Robotics: Crafting the Building Blocks of Automation

1. Precision Gears: Robots rely on precision gears to translate motor movement into precise actions. CNC machining enables the production of gears with custom profiles and tight tolerances, ensuring smooth and reliable operation.

2. Structural Components: The structural integrity of robotic systems is crucial for their functionality and longevity. CNC machining allows for the fabrication of lightweight yet durable structural components that withstand rigorous use.

3. Sensor Housings: Sensors play a vital role in robotic perception and navigation. CNC machining enables the fabrication of intricate sensor housings that protect sensitive components while ensuring optimal performance.

Pioneering New Energy Solutions: Precision for a Sustainable Future

1. Wind Turbine Components: The renewable energy sector demands components that can withstand harsh environmental conditions while maximizing energy output. Application of CNC machining enables the production of precision components for wind turbines, contributing to the efficiency and reliability of renewable energy systems.

2. Solar Panel Mounting Systems: Solar panels require robust mounting systems to ensure optimal positioning and stability. Application of CNC machining allows for the fabrication of customized mounting solutions that accommodate varying installation requirements.

3. Battery Enclosures: Energy storage is a critical component of renewable energy systems. CNC machining offers precise fabrication of battery enclosures with intricate cooling channels and custom configurations, optimizing battery performance and lifespan.

Elevating Furniture and Home Appliances: Precision Meets Aesthetics

1. Custom Hardware: Furniture manufacturers often require custom hardware to achieve unique designs and functionalities. CNC machining enables the production of bespoke hardware with intricate details and precise dimensions, enhancing the overall aesthetic appeal of furniture pieces.

2. Appliance Casings: Home appliances require durable and aesthetically pleasing casings to withstand daily use while complementing interior design schemes. CNC machining allows for the fabrication of appliance casings with smooth surfaces, intricate textures, and precise fitment.

3. Decorative Elements: From ornate trim pieces to decorative accents, CNC machining offers limitless possibilities for enhancing the visual appeal of furniture and home appliances. Insight Prototype's CNC machining services empower designers to bring their creative visions to life with precision and consistency.

Advancing Medical Equipment Manufacturing: Precision for Patient Care

1. Surgical Instruments: Surgical instruments must meet the highest standards of precision and reliability to ensure patient safety and surgical success. CNC machining enables the fabrication of surgical instruments with intricate geometries and fine details, meeting the exacting requirements of medical professionals.

2. Prosthetic Components: Custom prosthetics require precise fitting and functionality to restore mobility and improve the quality of life for patients. Application of CNC machining offers the precision necessary to produce prosthetic components tailored to each individual's unique anatomy and needs.

3. Medical Device Housings: The housings of medical devices must be durable, lightweight, and easy to clean to maintain sterility and patient safety. CNC machining allows for the fabrication of medical device housings with intricate features and custom configurations, meeting the stringent regulatory requirements of the healthcare industry.

Rapid CNC Machining Service: Speed and Precision Combined

When time is of the essence, Insight Prototype's rapid CNC machining service delivers unparalleled speed and precision. Equipped with state-of-the-art CNC machines and a team of experienced engineers, Insight Prototype ensures quick turnaround times without compromising on quality. Whether it's prototyping or production parts, clients can rely on Insight Prototype to deliver precision-engineered components with swift turnaround times, allowing them to stay ahead of the competition.

1. Speed: Insight Prototype understands the importance of meeting tight deadlines in today's fast-paced business environment. With the rapid Application of CNC machining capabilities, clients can expect expedited production times without sacrificing quality or accuracy.

2. Precision: Precision is the hallmark of CNC machining, and Insight Prototype excels in delivering components with tight tolerances and intricate geometries. Through meticulous attention to detail and advanced machining techniques, Insight Prototype ensures that every part meets the exact specifications of clients.

Polyurethane Vacuum Casting: Cost-Effective Prototyping and Low-Volume Production

For clients seeking cost-effective prototyping and low-volume production solutions, Insight Prototype's polyurethane vacuum casting service offers an ideal solution. This process allows for the rapid production of high-quality prototypes and small batch production runs using silicone molds and polyurethane resins. With Insight Prototype's expertise in polyurethane vacuum casting, clients can quickly iterate on designs, test functionality, and bring products to market faster and more affordably.

1. Versatility: Polyurethane vacuum casting is suitable for a wide range of applications, from automotive components to consumer electronics. Insight Prototype's expertise in this process enables clients to explore various materials, finishes, and configurations to meet their specific requirements.

2. Cost-Effectiveness: Compared to traditional manufacturing methods, polyurethane vacuum casting offers significant cost savings, particularly for low-volume production runs. Insight Prototype's efficient production processes and economies of scale further enhance cost-effectiveness, making it an attractive option for clients with budget constraints.

Low-Volume Production: Quality Without Compromise

Insight Prototype understands that not all projects require high-volume production. That's why the company offers low-volume production services tailored to the needs of clients. Whether it's for market testing, initial product launches, or niche markets, Insight Prototype's low-volume production capabilities ensure that clients receive high-quality components without the need for large minimum order quantities.

1. Flexibility: Insight Prototype's low-volume production services provide clients with the flexibility to scale production according to demand. Whether it's producing a handful of units or a few hundred, Insight Prototype can accommodate varying production volumes to meet client needs.

2. Quality Assurance: Despite the lower production volumes, Insight Prototype maintains the same rigorous quality standards for every part produced. From material selection to final inspection, each component undergoes thorough quality control measures to ensure consistency and reliability.

Anticipating Future Trends: Innovating with CNC Machining

1. Additive Manufacturing Integration: Redefining Production Processes

As additive manufacturing technologies continue to evolve, the integration of Application of CNC machining with 3D printing presents new opportunities for manufacturing. Insight Prototype recognizes the potential of this hybrid approach, combining the precision of CNC machining with the complexity and flexibility of 3D printing. By seamlessly integrating these technologies, Insight Prototype anticipates future trends and offers innovative solutions to meet the evolving needs of industries.

2. Digitalization and Automation: Streamlining Production Workflows

The future of CNC machining lies in digitalization and automation, where smart factories leverage data-driven insights to optimize production workflows. Insight Prototype invests in advanced automation technologies and digital tools to streamline manufacturing processes, reduce lead times, and enhance efficiency. By embracing digitalization and automation, Insight Prototype stays ahead of industry trends and delivers cutting-edge CNC machining solutions.

Conclusion: Meeting Diverse Needs with Unparalleled Precision

In summary, Application of CNC machining serves as a cornerstone technology across a wide range of industries, enabling manufacturers to achieve precision, efficiency, and innovation in their production processes. Insight Prototype Co., Ltd, with its advanced CNC machining capabilities and commitment to quality, stands as a trusted partner for businesses seeking to elevate their manufacturing capabilities. Backed by ISO 9001:2015 and ISO 13485 certifications, Insight Prototype delivers reliable solutions that meet the evolving needs of industries ranging from automotive to medical equipment. As industries continue to evolve and innovate, CNC machining will remain indispensable, driving progress and shaping the future of manufacturing.