Are You Maximizing Efficiency? Exploring the Benefits of CNC Order Services

Experience precision and efficiency with Insight Prototype Co., Ltd.'s CNC order services. From plastic machining advancements to seamless prototyping to production transitions, trust our expert team for quality assurance and timely delivery. Explore our range of materials and surface finishes today.

Introduction to CNC Order Machining Services

In today's fast-paced manufacturing landscape, precision and efficiency are paramount. CNC machining stands as a beacon of modern manufacturing, offering unparalleled accuracy and versatility. At the forefront of this technological revolution is Insight Prototype Co., Ltd., a leading provider of CNC order machining services.

CNC machining, short for Computer Numerical Control machining, is a method that utilizes computerized controls and machine tools to remove material from a workpiece, creating a custom-designed part or product. Its significance in manufacturing cannot be overstated, as it enables the production of highly intricate components with remarkable consistency and speed.

In the digital age, convenience is king. With online CNC order machining services, customers can now effortlessly access precision manufacturing solutions from the comfort of their own homes or offices. Insight Prototype Co., Ltd. offers a seamless online platform where customers can upload their designs, select from a wide range of materials and surface finishes, and receive immediate pricing for their projects.

The array of materials and surface finishes available through CNC order machining services is truly staggering. Whether it's metal or plastic, customers have access to over 40 materials and more than 10 surface finishes, allowing for the creation of parts tailored to their specific needs and requirements. From stainless steel to aluminum, and from matte to polished finishes, the possibilities are endless.

Quality assurance is paramount in the world of CNC machining. Insight Prototype Co., Ltd. understands this implicitly, which is why they hold ISO 9001:2015 and ISO 13485 certifications. These certifications serve as a testament to their unwavering commitment to delivering products of the highest quality, adhering to stringent standards and procedures every step of the way.

Exploring 5 Axis CNC Order Milling

When it comes to complex machining tasks, 5-axis CNC milling reigns supreme. Unlike traditional 3-axis machining, which limits movement along the X, Y, and Z axes, 5-axis machining adds two rotational axes, allowing for greater flexibility and precision. This versatility is invaluable in industries such as aerospace, automotive, and medical, where intricate geometries are the norm.

The advantages of 5-axis CNC milling are manifold. By enabling simultaneous movement of the cutting tool along multiple axes, 5-axis machining reduces setup time, increases accuracy, and minimizes the need for manual intervention. This results in shorter lead times, lower costs, and superior surface finishes, all of which translate to a competitive edge in the marketplace.

The capabilities of 5-axis CNC milling are truly awe-inspiring. From complex contours to intricate curves, virtually any shape can be machined with unparalleled accuracy and efficiency. Industries ranging from aerospace and automotive to healthcare and defense rely on 5-axis machining for the production of critical components such as turbine blades, engine blocks, and medical implants.

Understanding CNC Order Metal Machining

CNC order metal machining is a subtractive manufacturing process wherein material is selectively removed from a solid block of metal to create a custom-designed part or product. This process offers numerous benefits, including high precision, repeatability, and the ability to work with a wide range of metals, including aluminum, stainless steel, titanium, and brass.

The applications of CNC order metal machining are as diverse as the metals themselves. From aerospace components to automotive parts, medical devices to consumer electronics, CNC machining plays a vital role in the production of countless products across a myriad of industries. Its ability to deliver complex geometries with tight tolerances makes it indispensable in the modern manufacturing landscape.

Choosing the right material is crucial in CNC order metal machining. Insight Prototype Co., Ltd. offers a comprehensive selection of materials suitable for CNC machining, each with its own unique properties and characteristics. Whether it's the lightweight versatility of aluminum, the corrosion resistance of stainless steel, or the strength-to-weight ratio of titanium, customers can rest assured knowing that their material needs will be met with precision and expertise.

Unlocking Potential: Exploring CNC Order Plastic Machining

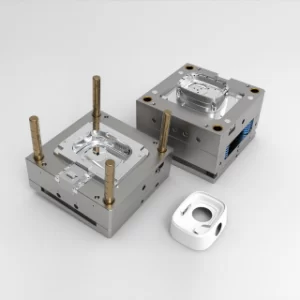

CNC order plastic machining has seen significant advancements in recent years, revolutionizing the way plastic components are manufactured. With the aid of cutting-edge technology, Insight Prototype Co., Ltd. has pushed the boundaries of what's possible, delivering precision and quality in every plastic part produced. From rapid prototyping to full-scale production, CNC order plastic machining offers unmatched versatility and efficiency.

The versatility of CNC order plastic machining knows no bounds. From simple prototypes to complex components, CNC machining can handle a wide range of shapes, sizes, and intricacies with ease. This flexibility makes it ideal for a myriad of applications across various industries, including automotive, aerospace, medical, consumer electronics, and more. Whether it's creating custom housings, enclosures, brackets, or intricate components, CNC order plastic machining delivers unparalleled precision and reliability.

A key aspect of CNC order plastic machining is the selection of the right material for the job. Insight Prototype Co., Ltd. offers a comprehensive range of plastics suitable for CNC machining, each with its own unique properties and characteristics. Common plastics used in CNC machining include ABS, acrylic, nylon, polycarbonate, and PEEK, among others. These materials vary in terms of strength, rigidity, temperature resistance, chemical resistance, and surface finish, allowing customers to choose the most suitable option for their specific application.

One of the standout features of CNC order services is their ability to seamlessly transition from prototyping to production. What starts as a concept or idea can quickly evolve into a fully realized product, thanks to the precision and efficiency of CNC machining. Insight Prototype Co., Ltd. offers comprehensive support throughout the entire lifecycle of a project, from initial design and prototyping to full-scale production, ensuring a smooth and streamlined process every step of the way.

The benefits of using CNC order services for prototyping and low-volume production are manifold. By leveraging CNC machining, customers can quickly and cost-effectively iterate on designs, test concepts, and validate ideas before committing to full-scale production. This agility and flexibility allow for faster time-to-market and reduced development costs, giving businesses a competitive edge in today's fast-paced market environment.

Insight Prototype Co., Ltd. boasts state-of-the-art CNC machining facilities equipped with the latest technology and machinery. Their team of highly skilled engineers, machinists, and technicians ensures the highest level of quality and precision in every part produced. Adhering to strict quality standards and certifications, including ISO 9001:2015 and ISO 13485, they guarantee the reliability, consistency, and performance of their products. With a focus on continuous improvement and innovation, Insight Prototype Co., Ltd. remains at the forefront of CNC order machining, delivering excellence with every project.

Efficiency and Quality Assurance: The Backbone of CNC Order Machining

Technology plays a pivotal role in ensuring efficiency in CNC order machining. From advanced CAD/CAM software for design and programming to high-speed machining centers for production, every aspect of the process is optimized for maximum productivity and precision. Insight Prototype Co., Ltd. leverages the latest technological advancements to streamline workflows, minimize setup times, and optimize machining parameters, resulting in faster turnaround times and superior quality.

At Insight Prototype Co., Ltd., quality assurance is ingrained in every aspect of the operation. Their team of dedicated professionals includes R&D experts, machinists and quality control experts. Works tirelessly to maintain the highest standards of quality and reliability. Through rigorous inspection protocols, ongoing training and adherence to best practices. They ensure every part meets or exceeds customer expectations. Winning the trust and confidence of customers around the world.

An efficient workflow is essential in reducing lead times and ensuring timely delivery of products. Insight Prototype Co., Ltd. understands the importance of a well-optimized process, from initial inquiry to final delivery. By streamlining operations, minimizing waste, and optimizing resource allocation, they are able to deliver projects on time and within budget, without compromising on quality or precision. This commitment to efficiency and excellence sets them apart as a leader in the field of CNC order machining, driving innovation and success in every endeavor.

Conclusion

CNC order machining services represent the epitome of modern manufacturing, offering unparalleled precision, efficiency, and versatility. At the helm of Insight Prototype Co., Ltd. Clients can trust that their project will be handled with the utmost care and professionalism from start to finish. Whether it's 5-axis CNC milling or CNC-to-order metal machining. The possibilities are endless and the results are extraordinary.