Quick Turnaround: The Art of Rapid Prototyping for Small-Scale Production

Rapid prototyping is pivotal in small-scale production as it accelerates the design process, allowing creators to quickly transform ideas into tangible models. This immediacy aids in the identification of design flaws, fostering swift iterations and refinements. For small businesses, it can mean faster time-to-market, optimized costs, and more adaptive responses to market needs. In essence, rapid prototyping is a catalyst for innovation and efficiency in compact production settings.

What is Rapid Prototyping?

Definition and Explanation

Rapid prototyping is a design and manufacturing strategy that quickly crafts physical models or simulations using computer-aided design (CAD) data. Rather than following traditional, time-consuming, and often costly manufacturing methods, it employs techniques like 3D printing to produce parts or models swiftly. This rapid iteration capability allows designers and engineers to visualize, test, and refine a concept in a tactile form.

Role in Product Development and Design

Rapid prototyping plays a transformative role in the product development lifecycle. Its foremost advantage lies in early visualization, providing stakeholders with a tangible or virtual representation of the product, which is invaluable for making informed decisions. By translating abstract ideas into something concrete, it becomes easier to grasp potential design flaws or enhancements.

From Feedback to Flawless Design

Furthermore, when a prototype exists, feedback can be collected from potential users, stakeholders, or team members, allowing iterative improvements to be made before finalizing the design. This not only reduces costly errors but also ensures that the final product meets user needs and market expectations. By facilitating iterative design, rapid prototyping truncates product development timelines, reduces costs, and amplifies the potential for innovative solutions. In essence, it stands as a cornerstone for efficient and effective design processes in modern product development.

Benefits of Rapid Prototyping for Small-Scale Production

Small-scale production has unique challenges and demands that can be proficiently addressed through rapid prototyping. Here are its key advantages:

Cost Savings

Traditional manufacturing processes can be costly, especially for short production runs. Rapid prototyping minimizes upfront tooling costs and material wastage. When changes are needed, they can be implemented without expensive mold alterations.

Design Flexibility

One of the hallmarks of rapid prototyping is the ease with which designs can be tweaked. For small businesses or niche products, this means the ability to adapt to market feedback quickly, ensuring the product remains relevant and meets customer demands.

Reduced Time-to-Market

In competitive markets, the speed at which a product reaches consumers can be the difference between success and obscurity. Rapid prototyping accelerates the design and testing phases, ensuring faster product launches.

In essence, for small production runs, rapid prototyping isn't just an advantage; it's a necessity. It empowers creators, offering them the flexibility, efficiency, and speed essential for thriving in dynamic market conditions.

Exploring Core Techniques in Rapid Prototyping

The realm of rapid prototyping is rich with diverse technologies and methods, each fine-tuned to address distinct design and manufacturing requirements. Delving into some of these prominent techniques:

3D Printing

Standing as a hallmark of modern prototyping, 3D printing fabricates items layer upon layer, utilizing materials ranging from resins and metals to thermoplastics. It is revered for its expediency, adaptability, and capacity to craft complex structures often challenging for conventional methods.

CNC Machining

Through the guidance of computer instructions, CNC machining carves out a desired component from a solid block. It earns accolades for its meticulous precision and the capability to fashion robust prototypes that mirror the final product's material.

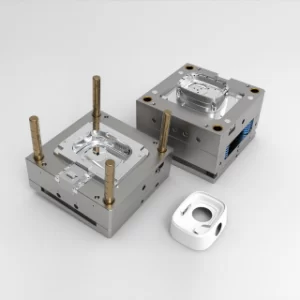

Injection Molding

While conventionally associated with mass production, recent strides in mold technology have ushered injection molding into the rapid prototyping sphere. It's particularly beneficial when there's a need for numerous prototype replicas in a short span.

Collectively, these methodologies, alongside others, serve as the pillars of rapid prototyping. They equip designers and engineers with the arsenal to swiftly materialize their innovative visions. With an appreciation for the advantages and confines of each technique, creators are better poised to select the optimal path for their unique project endeavors.

Challenges and Considerations in Rapid Prototyping

Embracing rapid prototyping for small-scale production offers numerous advantages, but it also comes with its set of challenges and considerations:

Material Selection

The variety of materials available for techniques like 3D printing is vast, but not all are suited for functional testing or end-use. Ensuring that the chosen material aligns with the desired prototype function and durability is crucial.

Cost Implications

While rapid prototyping can reduce overall project costs, the initial investment in equipment and technology might be significant. Additionally, certain materials or processes may be more expensive than traditional methods, making it essential to weigh the benefits against the costs.

Quality Control

Ensuring consistent quality can be a challenge, especially when moving from one prototyping method to another or switching materials. Variations in layer thickness, post-processing needs, or even material batches can affect the prototype's final quality.

Incorporating rapid prototyping into small-scale production demands a holistic approach, considering not only the immediate benefits but also potential challenges. By acknowledging these factors and strategizing accordingly, manufacturers can effectively harness the power of rapid prototyping while mitigating its challenges.

Future Trends in Rapid Prototyping for Small Production

Rapid prototyping is in a constant state of evolution, with emerging technologies shaping the future of small-scale production:

- Material Innovations

Beyond traditional resins and plastics, we're seeing the rise of advanced composite materials, bio-materials, and smart materials that can adapt or respond to their environment.

- AI and Machine Learning

These technologies are streamlining design processes, predicting potential design flaws, and optimizing material usage, reducing both time and waste.

- Augmented Reality (AR) and Virtual Reality (VR)

AR and VR tools allow designers to visualize and test prototypes in virtual spaces, enhancing design precision and user interaction without creating a physical model.

- Sustainability Focus

As environmental concerns mount, there's a push towards eco-friendly materials and processes that reduce waste and energy consumption.

These advancements promise not only enhanced efficiency and precision but also a broader realm of possibilities in design and functionality for small-scale production.

In Conclusion

Rapid prototyping stands as a transformative force in the landscape of small-scale production, merging technology, creativity, and efficiency. As it continues to evolve, it reshapes our approach to design, testing, and production, turning ideas into tangible realities at unparalleled speeds. This art of quick turnaround, blending precision with adaptability, promises to remain a pivotal asset for innovators and entrepreneurs, ensuring that their visions reach the market with agility and relevance.