How Do Machine Products Impact Efficiency and Productivity in Manufacturing?

At the forefront of modern manufacturing, Rapid CNC Machining stands as a pivotal technology, driving efficiency and innovation in the production of machine products. As an industry leader in this field, Insight Prototype Co., Ltd. recognizes the paramount importance of Rapid CNC Machining in streamlining the development process and delivering high-quality, custom-machined parts. Let's delve into the intricacies of Rapid CNC Machining and its indispensable role in machine product manufacturing.

Understanding Rapid CNC Machining: The Backbone of Efficient Machine Product Development

1.1 Introduction to Rapid CNC Machining for Machine Product Manufacturing

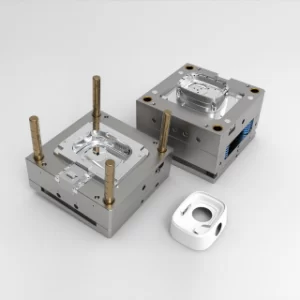

Rapid CNC Machining, also known as Computer Numerical Control machining, revolutionizes the manufacturing landscape by offering unparalleled precision, speed, and versatility. By utilizing advanced software and automated machinery, Rapid CNC Machining expedites the production of custom-machined parts, catering to the unique requirements of machine product development. Insight Prototype Co., Ltd. harnesses this cutting-edge technology to bring concepts to life swiftly and efficiently.

1.2 Expedited Development Process

One of the key advantages of Rapid CNC Machining is its ability to significantly reduce the time required for product development. Traditional manufacturing methods often involve lengthy lead times and extensive manual labor. In contrast, Rapid CNC Machining streamlines the process, allowing for rapid prototyping and iteration. Insight Prototype Co., Ltd. leverages this accelerated development cycle to meet tight deadlines and deliver superior machine products to their clients.

1.3 Benefits of CNC Machines in Machine Product Manufacturing

CNC machines play a pivotal role in the manufacturing of machine products due to their precision, repeatability, and flexibility. With CNC machines, intricate designs can be realized with utmost accuracy, ensuring the production of high-quality components. Insight Prototype Co., Ltd. harnesses the power of CNC machines, boasting over 15 multi-axis models, to craft custom-machined parts tailored to the exact specifications of their clients.

Exploring the Role of Multi-Axis CNC Machines in Machine Product Fabrication

2.1 Overview of Multi-Axis CNC Machines

Multi-axis CNC machines represent the pinnacle of machining technology, offering unparalleled freedom of movement and precision. By incorporating advanced axis configurations, such as 3, 4, and 5-axis models, these machines excel at machining complex geometries with intricate details. Insight Prototype Co., Ltd. embraces the capabilities of multi-axis CNC machines, enabling them to tackle the most challenging machine product fabrication tasks with ease.

2.2 Advantages of Multi-Axis Machining

Case studies abound in showcasing the advantages of multi-axis machining for machine product components. From intricate aerospace parts to sophisticated medical devices, multi-axis CNC machines deliver exceptional results across various industries. Insight Prototype Co., Ltd. exemplifies these advantages through its portfolio of successful projects, demonstrating its proficiency in leveraging multi-axis capabilities to achieve unparalleled precision and versatility.

2.3 Enhanced Precision and Versatility

The inherent flexibility of multi-axis CNC machines allows for the simultaneous machining of multiple surfaces, minimizing setup times and maximizing productivity. This level of precision and versatility is indispensable in the fabrication of machine products, where complex geometries and tight tolerances are the norm. Insight Prototype Co., Ltd. capitalizes on the capabilities of multi-axis machining to fulfill the diverse needs of its clients, ensuring the production of flawless machine components.

Materials and Finishes: Customization Options for Optimal Machine Product Performance

3.1 Extensive Selection of Materials and Finishes

In Rapid CNC Machining, material selection plays a pivotal role in determining the performance and durability of machine product components. Insight Prototype Co., Ltd. offers an extensive selection of materials, ranging from metals to plastics, each with its unique properties and characteristics. Whether it's aluminum for lightweight aerospace applications or stainless steel for rugged industrial machinery, clients can choose the ideal material to suit their specific requirements.

3.2 Guidance on Material Selection

Selecting the right material is paramount in achieving optimal machine product performance. Insight Prototype Co., Ltd. provides expert guidance to clients, helping them navigate the myriad of material options available. Factors such as mechanical properties, chemical resistance, and thermal conductivity are carefully considered to ensure compatibility with the intended application. By offering tailored recommendations, Insight Prototype Co., Ltd. ensures that clients receive machine products of the highest quality and functionality.

3.3 Impact of Material Selection

The choice of material has a profound impact on the functionality and durability of machine product components. Whether it's achieving exceptional strength-to-weight ratios or corrosion resistance in harsh environments, the right material can make all the difference. Insight Prototype Co., Ltd. collaborates closely with clients to understand their unique requirements and recommend materials that optimize performance and longevity. By prioritizing quality and precision in material selection, Insight Prototype Co., Ltd. sets the standard for excellence in machine product manufacturing.

4.1 Step-by-Step Explanation of the Rapid Turnaround Process

Rapid CNC Machining offers an expedited pathway from design to production, revolutionizing the traditional manufacturing timeline. Insight Prototype Co., Ltd. provides a comprehensive breakdown of the rapid turnaround process, starting from initial concept ideation to the final product realization. By leveraging advanced CAD/CAM software and state-of-the-art CNC machines, they streamline every stage of the process, ensuring maximum efficiency and precision.

4.2 Strategies for Expediting Design Iterations and Prototype Development

Central to the rapid turnaround process is the iterative nature of design and prototyping. Insight Prototype Co., Ltd. implements strategies to expedite design iterations, allowing for quick adjustments and refinements based on client feedback. Through collaborative design sessions and rapid prototyping techniques, they accelerate the development timeline, reducing time-to-market for machine products. By embracing a culture of innovation and agility, Insight Prototype Co., Ltd. empowers clients to iterate rapidly and iterate often, ultimately leading to superior machine product outcomes.

4.3 Tips for Optimizing Collaboration Between Designers and Manufacturers

Effective collaboration between designers and manufacturers is paramount in achieving rapid turnaround times in machine product development. Insight Prototype Co., Ltd. emphasizes open communication channels and seamless integration between design and manufacturing teams. By fostering a collaborative environment, they ensure that design specifications are translated accurately into machined parts, minimizing errors and reducing lead times. Through proactive communication and shared project management tools, Insight Prototype Co., Ltd. facilitates a smooth and efficient collaboration process, resulting in the timely delivery of high-quality machine products.

Quality Assurance in Rapid CNC Machining: Ensuring Precision and Reliability in Machine Product Manufacturing

5.1 Overview of Quality Control Measures

Quality assurance lies at the heart of Rapid CNC Machining, ensuring that machine products meet stringent performance and reliability standards. Insight Prototype Co., Ltd. implements robust quality control measures throughout the manufacturing process, from material selection to final inspection. By adhering to strict quality standards and industry best practices, they guarantee the consistency and accuracy of machined components, instilling confidence in their clients.

5.2 Discussion on Inspection Techniques and Quality Assurance Protocols

Insight Prototype Co., Ltd. employs a range of inspection techniques and quality assurance protocols to validate the integrity of machine product components. From dimensional accuracy checks to surface finish evaluations, every aspect of the part is meticulously scrutinized to ensure compliance with design specifications. By leveraging advanced metrology equipment and experienced quality control personnel, they uphold the highest standards of precision and reliability in machine product manufacturing.

5.3 Importance of Quality Assurance

Quality assurance is paramount in achieving high-performance and reliable machine products that meet or exceed customer expectations. Insight Prototype Co., Ltd. recognizes that quality is non-negotiable and prioritizes it at every stage of the manufacturing process. By investing in state-of-the-art technology and continuous process improvement initiatives, they uphold their commitment to delivering excellence in machine product manufacturing.

Conclusion

In conclusion, Rapid CNC Machining stands as the cornerstone of efficient machine product development, offering unparalleled speed, precision, and customization options. Insight Prototype Co., Ltd. exemplifies excellence in this field, leveraging advanced technologies and expertise to deliver superior machine products to their clients. Through the integration of multi-axis CNC machines and meticulous material selection processes, Insight Prototype Co., Ltd. ensures the production of high-quality, custom-machined parts tailored to the exact specifications of their clients.