How Can CNC Milling Services Innovate Your Furniture Project Designs?

Uncover the transformative impact of CNC milling services from Insight Prototype Co., Ltd on furniture and home appliance manufacturing. Delve into precision parts processing, efficiency gains, and creative design possibilities, backed by real case studies. Elevate your production processes and enhance product quality with Insight Prototype Co., Ltd's unmatched expertise in CNC technology.

Introduction to CNC Milling Services for Furniture and Home Appliances

In the dynamic landscape of manufacturing, CNC milling services have emerged as a cornerstone technology, driving innovation and efficiency in the production of furniture and home appliances. This section provides an introductory glimpse into the world of CNC milling, its crucial role in shaping the industry, and the specific benefits it brings to manufacturers in these sectors.

1.1 Understanding CNC Milling

CNC milling, short for Computer Numerical Control milling, is a cutting-edge manufacturing process that utilizes computerized controls and precise machinery to shape raw materials into finished products. In the realm of furniture and home appliances, CNC milling has revolutionized traditional manufacturing methods by offering unparalleled precision, efficiency, and repeatability.

1.2 Applications in Furniture and Home Appliances

The application of CNC milling in furniture and home appliances is vast and varied. From crafting intricate furniture pieces to manufacturing sleek appliance shells, CNC technology enables manufacturers to bring their designs to life with unprecedented accuracy and consistency. This level of precision is especially crucial in industries where quality and aesthetics are paramount.

1.3 Yunsheng Technology's One-Stop Service Approach

Yunsheng Technology, a leading CNC miller service provider, offers a comprehensive suite of solutions tailored to the unique needs of furniture and home appliance manufacturers. Their one-stop service approach streamlines the manufacturing process, from design conception to final production, saving both time and resources for their clients. By partnering with Yunsheng Technology, manufacturers can benefit from cost-saving measures and expedited project timelines, all while maintaining the highest standards of quality.

Advantages of CNC Furniture Manufacturing

CNC technology has ushered in a new era of efficiency and precision in furniture manufacturing, revolutionizing the way designers and manufacturers approach their craft. This section delves deeper into the specific advantages of CNC technology in the realm of furniture production, highlighting its transformative impact on the industry.

2.1 Enhanced Design Capabilities

One of the primary advantages of CNC furniture manufacturing lies in its ability to bring complex designs to fruition with unparalleled precision. By leveraging advanced CAD design software and CNC machining capabilities, designers can explore innovative shapes, intricate patterns, and unique geometries that were once deemed unattainable. This flexibility in design empowers manufacturers to push the boundaries of creativity and create truly bespoke furniture pieces that captivate the imagination.

2.2 Material Versatility

Another key advantage of CNC furniture manufacturing is its inherent material versatility. Unlike traditional manufacturing methods that may be limited to specific materials, CNC machining can accommodate a wide range of substrates, including wood, metal, plastic, and composite materials. This versatility allows manufacturers to select the most suitable materials for their projects, whether it's for durability, aesthetics, or functionality, without compromising on quality or design.

2.3 Precision and Repeatability

Precision is the hallmark of CNC machining, and nowhere is this more evident than in the realm of furniture manufacturing. CNC machines can achieve incredibly tight tolerances and consistent results, ensuring that each piece produced is of the highest quality. Whether it's intricate joinery, fine detailing, or complex geometries, CNC technology delivers unparalleled precision and repeatability, elevating the overall craftsmanship of the finished product.

2.4 Mass Production Capabilities

In addition to its precision and versatility, CNC technology also excels in mass production scenarios. With its automated processes and efficient workflows, CNC machining enables manufacturers to scale their production volumes without sacrificing quality or efficiency. This scalability is particularly advantageous in industries where demand fluctuates or where large quantities of identical or similar products are required.

CNC Home Appliance Manufacturing: Shell Production

The manufacturing of home appliance shells is a critical aspect of the production process, requiring precision, consistency, and attention to detail. In this section, we explore the role of CNC technology in shell production for home appliances, highlighting its versatility, efficiency, and suitability for meeting the unique requirements of this sector.

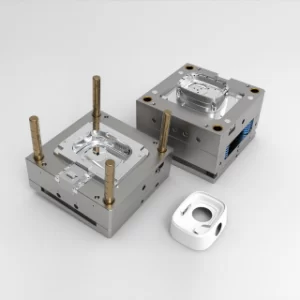

3.1 Precision Shell Manufacturing

CNC technology offers unparalleled precision in the manufacturing of home appliance shells, ensuring that each component meets exacting specifications and standards. From the sleek contours of a refrigerator door to the intricate details of a washing machine lid, CNC machining delivers precise results with exceptional accuracy and consistency.

3.2 Versatility in Design

One of the key advantages of CNC shell production is its versatility in design. Unlike traditional manufacturing methods that may be limited by tooling constraints or material properties, CNC machining allows for the creation of shells in virtually any shape, size, or configuration imaginable. This flexibility enables designers to explore innovative designs and aesthetics, from minimalist profiles to bold, sculptural forms, without compromising on functionality or performance.

3.3 Meeting Diverse Requirements

Home appliances come in a wide range of shapes, sizes, and configurations, each with its own unique set of design and manufacturing requirements. CNC technology excels in meeting these diverse requirements, offering the flexibility and precision needed to produce shells for various appliances, including refrigerators, washing machines, ovens, and more. Whether it's a custom enclosure for a high-tech gadget or a standard housing for a household appliance, CNC machining can adapt to the specific needs of each project with ease.

3.4 Expertise in Shell Production

Yunsheng Technology boasts extensive expertise in the production of shells for various home appliances, leveraging their advanced CNC milling capabilities to deliver superior results for their clients. Their team of skilled engineers and technicians works closely with clients to understand their unique requirements and specifications, ensuring that each shell is manufactured to the highest standards of quality and craftsmanship. From prototype development to mass production, Yunsheng Technology provides end-to-end solutions that meet the evolving needs of the home appliance industry.

Efficiency and Innovation: CNC Solutions for Furniture and Home Appliances

In today's fast-paced manufacturing environment, efficiency and innovation are key drivers of success. CNC (Computer Numerical Control) solutions have revolutionized the furniture and home appliance industries, offering unprecedented efficiency gains, cost savings, and opportunities for creative expression. This section explores the myriad benefits of CNC technology in both sectors, highlighting its transformative impact on production processes and design capabilities.

4.1 Efficiency Gains

CNC technology streamlines production processes in furniture and home appliance manufacturing, resulting in significant efficiency gains and reduced lead times. Automated CNC machining eliminates the need for manual intervention, reducing labor costs and human error while accelerating production cycles. Moreover, CNC machines operate continuously with minimal downtime, maximizing productivity and throughput to meet demanding production schedules.

4.2 Mass Production Capabilities

One of the most significant advantages of CNC technology is its ability to facilitate mass production of furniture and home appliances with unparalleled consistency and quality. CNC machines excel at replicating identical parts with precision, enabling manufacturers to scale production volumes rapidly while maintaining product integrity. Whether it's producing hundreds of identical chair legs or thousands of appliance shells, CNC technology ensures uniformity and reliability across the entire production run.

4.3 Cost Savings

CNC solutions offer substantial cost savings for furniture and home appliance manufacturers through reduced material wastage, labor efficiencies, and optimized production processes. By minimizing errors and maximizing material utilization, CNC machining minimizes scrap and rework costs, resulting in higher overall profitability. Additionally, the efficiency gains achieved through CNC technology translate into lower production costs per unit, enabling manufacturers to remain competitive in the market without compromising on quality or innovation.

4.4 Innovative Design Possibilities

CNC technology empowers designers and engineers to explore innovative design possibilities that were previously unattainable with traditional manufacturing methods. From intricate furniture patterns to futuristic appliance aesthetics, CNC machining unlocks a world of creative expression and customization. By leveraging advanced CAD (Computer-Aided Design) software and CNC machining capabilities, designers can bring their vision to life with precision and accuracy, pushing the boundaries of conventional design and inspiring new trends in furniture and home appliance aesthetics.

4.5 Examples of Innovative Designs

The versatility of CNC technology enables manufacturers to realize a wide range of innovative designs in furniture and home appliances. For instance, CNC-machined furniture pieces can feature intricate lattice structures, organic curves, and geometric patterns that blur the line between art and function. Similarly, CNC-machined appliance enclosures can boast sleek contours, seamless transitions, and integrated features that enhance both form and function. These innovative designs not only captivate consumers' attention but also elevate the perceived value and desirability of the products, driving sales and brand differentiation in a competitive market landscape.

Conclusion: Driving Innovation in Manufacturing

In conclusion, CNC milling services provided by Insight Prototype Co., Ltd offer a glimpse into the future of manufacturing for furniture and home appliances. With its precision, efficiency, and versatility, CNC technology has revolutionized the way products are designed and fabricated, opening up endless possibilities for innovation and creativity. Whether it's crafting intricate furniture designs or manufacturing precision appliance shells, Insight Prototype Co., Ltd's expertise in CNC milling ensures that every project is executed with the utmost precision and care, delivering superior results that exceed expectations.